THe Source

OFFROAD BLOG

The Source is a collection of purposeful posts that help simply some of the biggest (and most confusing) topics in offroading. For everyone's safety, we want all of our customers to be educated before they hit any trail. The Source is here to help. Did we miss a topic? Hit us up @valoroffroad

What is a Segmented Tire Mold?

Wheel Offset vs. Backspacing

Do UTV Tires Need to be Balanced?

Wide Stance UTV Wheel Kits

What happens when a tire is over inflated?

What is a Wheel PCD and How to Measure

Polaris Xpedition Accessories

UTV Sand Kit Buyers Guide

CanAm Maverick R Wheels & Tires

Principles of Tread Lightly!

How are UTV Wheels Measured?

ATV Tires vs UTV Tires

Best 2025 UTV Events

UTV Tires 101 Crash Course

How to choose the right UTV Wheel

Does lightweight matter?

What are DOT approved UTV Tires?

Rims or Wheels? What's the difference?

What is a Flow Formed Wheel?

How is a tire made?

What is the best UTV wheel

Top 10 items you need in your trailer

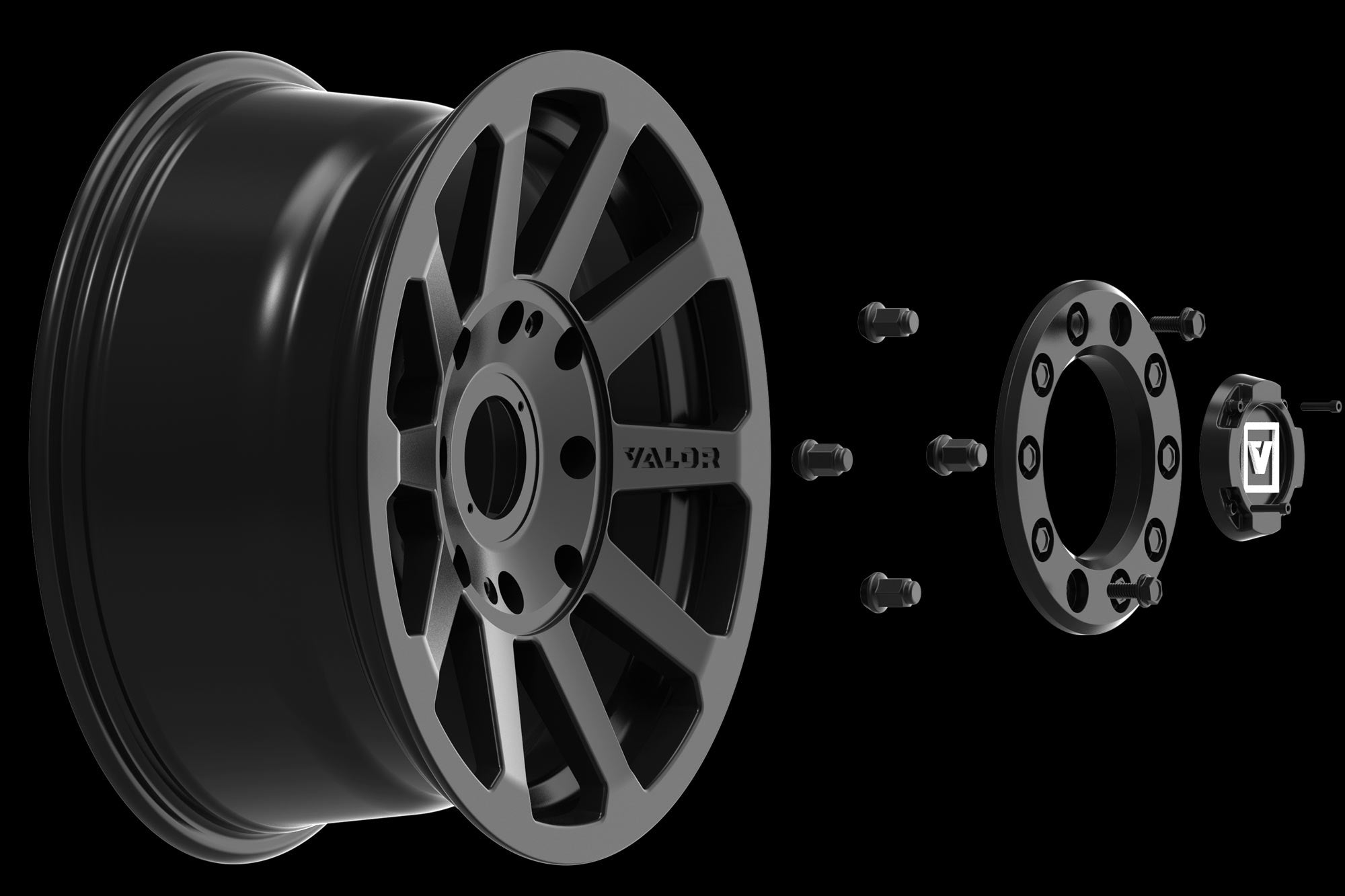

What is a Dual-Drill UTV Wheel?

Tire Durometer Ratings

Unsprung vs Sprung Weight

Restoring an older UTV or ATV

How to Install Beadlock Wheels

Explain Tire Sidewall Marks

What is a tire bead gap

How much does a UTV weight?

Guide to buying a UTV or ATV

What is a bolt pattern?

Tire Pressure on Your UTV

What is a Centerbore?

UTV Tires Made in the USA

What makes Valor Different

Why you should tighten your lugs

What is a tire section width?

Valor Offroad Casting Process

What Exactly is An Overland Vehicle?

How to handle a flat tire

SRA vs IRS ATV

UTV Gear Checklist

New Polaris UTV Wheels & Tires

Winter Offroading Packing List

Why Do I Need New Lug Nuts

What is the Best UTV Trailer?