What is Billet Aluminum?

Billet aluminum is a solid chunk or block of aluminum, typically formed by casting or rolling into basic shapes (like rounds or squares) that is then precisely machined (carved/cut) into a final, complex part, rather than being melted and poured into a mold (casting). This process produces parts with superior strength, tighter tolerances, and a consistent grain structure, making it ideal for high-performance applications where durability and precision matter most, despite its higher cost compared to cast aluminum.

How it's Made: Starting Material: A solid block (billet) of aluminum alloy, often 6061-T6. Shaping: Computer Numerical Control (CNC) machines cut, drill, and mill away material from the solid block. Result: A precisely shaped component with uniform metal grain, eliminating the porosity or weaknesses found in cast parts.

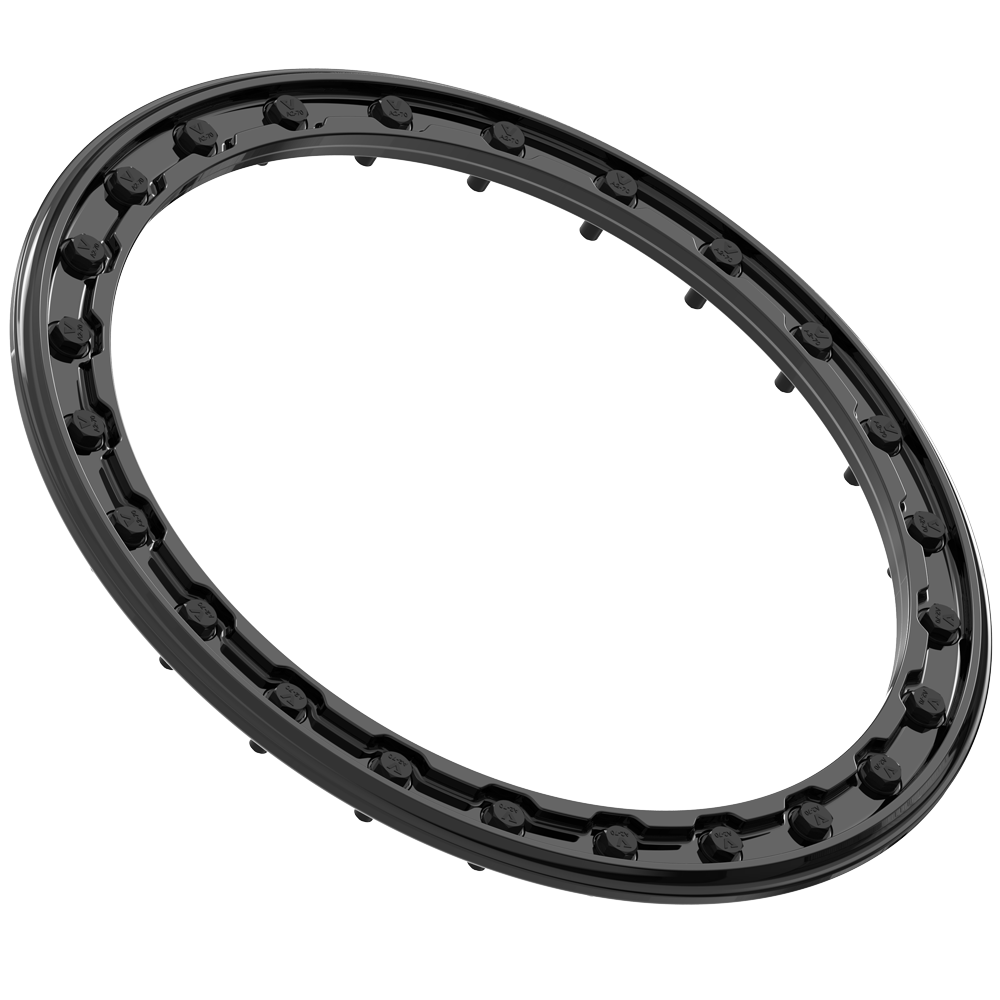

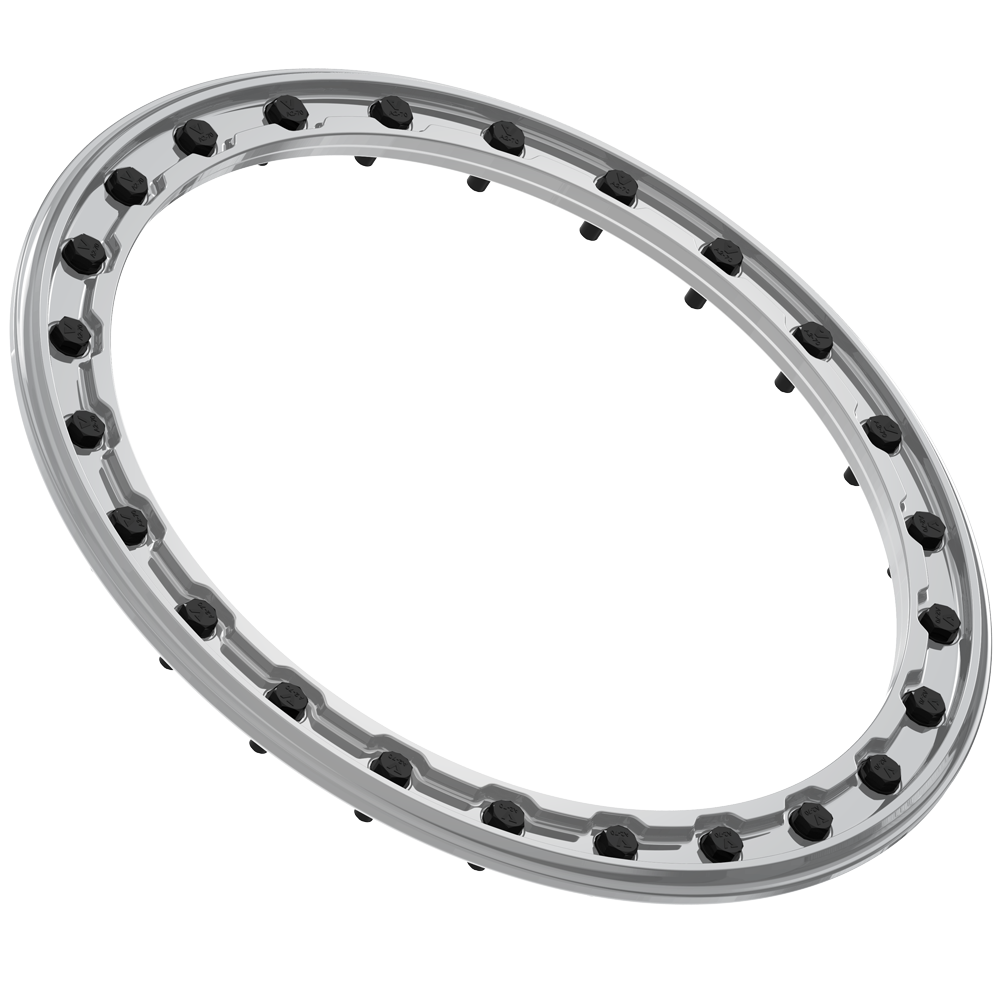

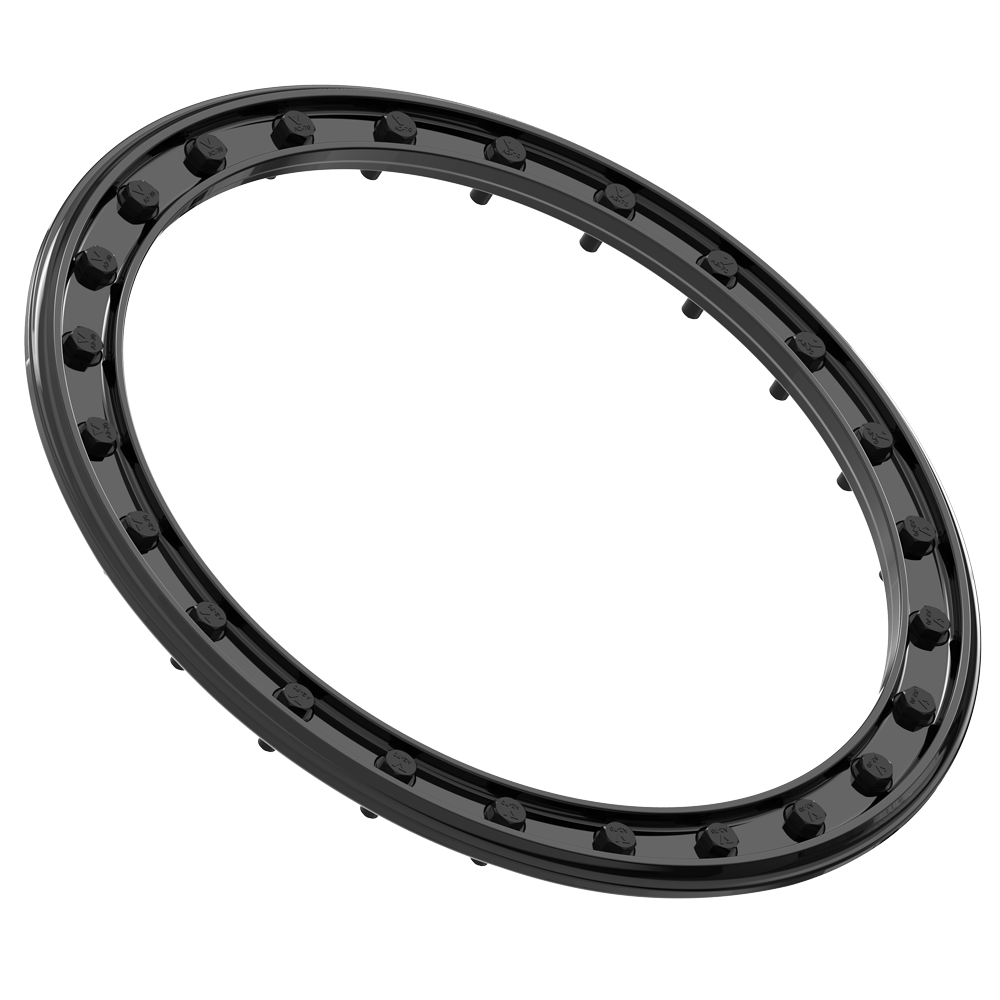

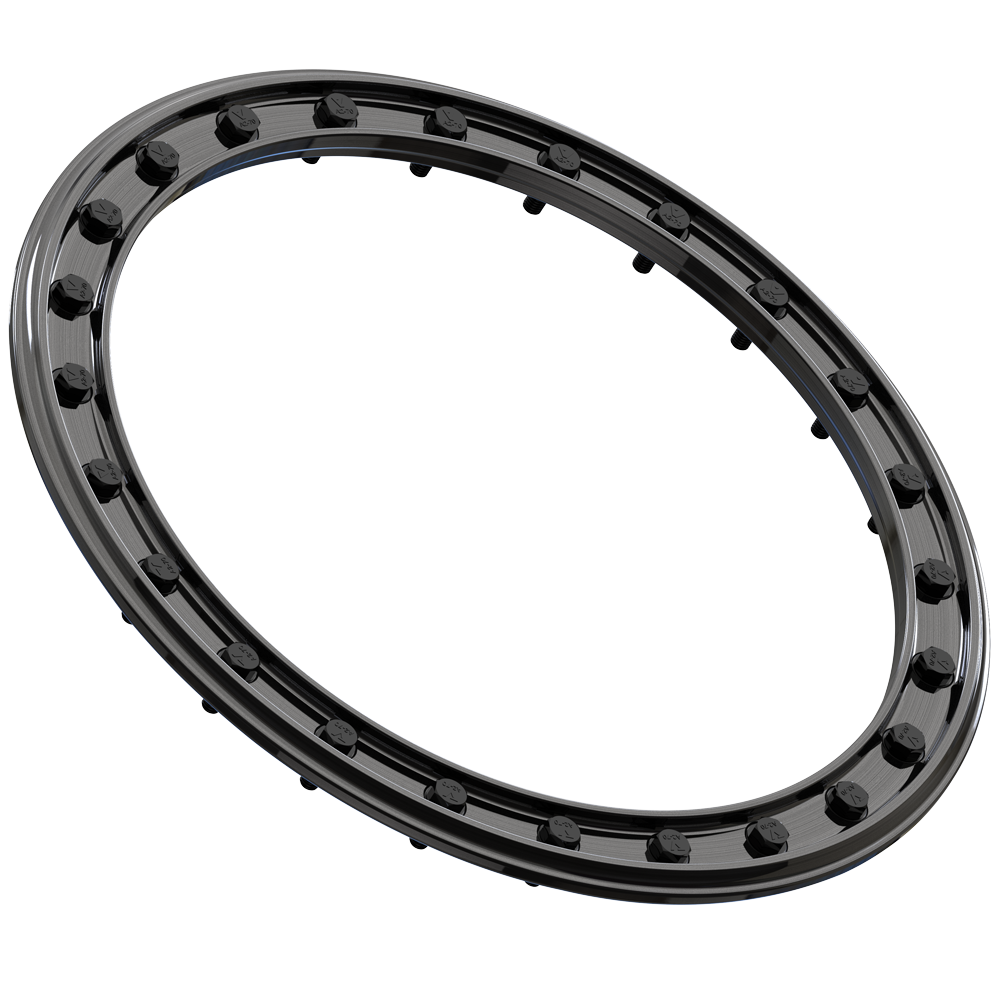

Key Characteristics & Benefits: Strength: Generally stronger and more durable than cast parts due to consistent grain structure. Precision: Allows for extremely tight tolerances and complex designs. Appearance: Often has a distinct, machined look, popular in custom parts. Applications: Used for high-stress components like pistons, connecting rods, suspension parts, and custom aftermarket parts.

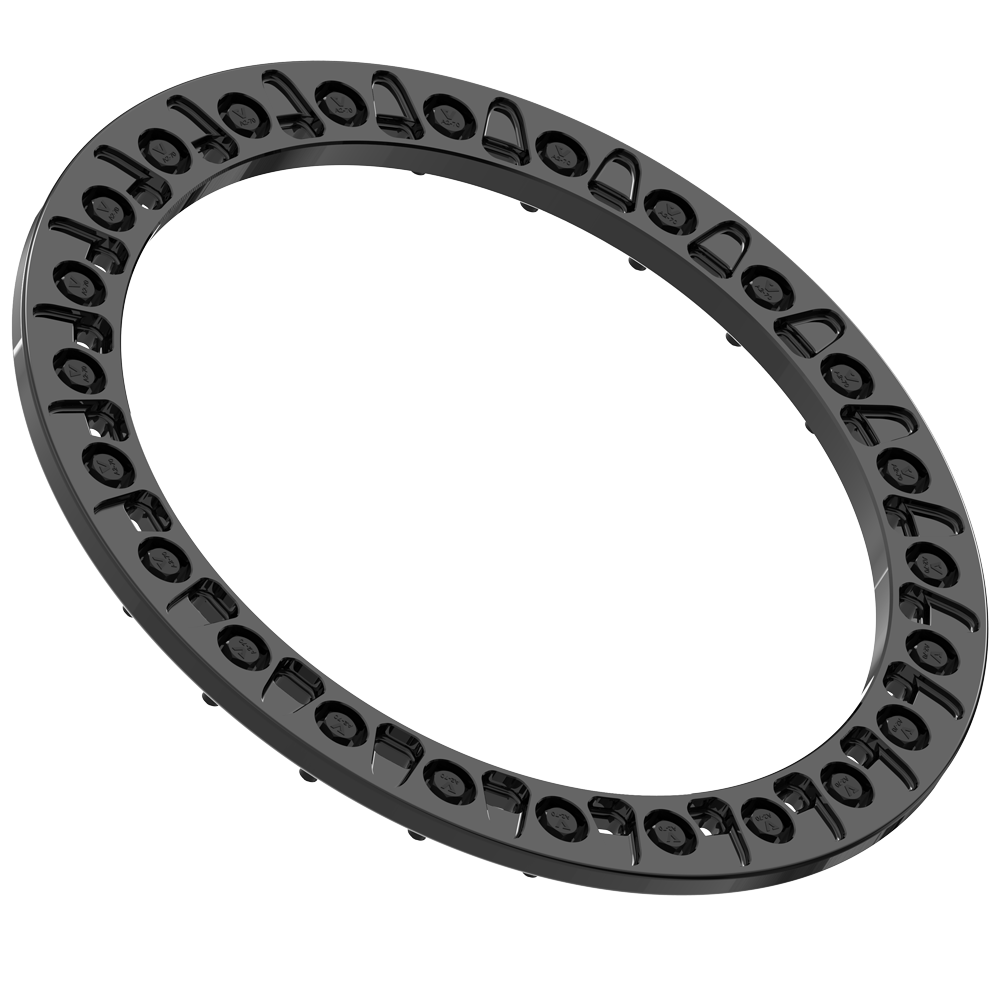

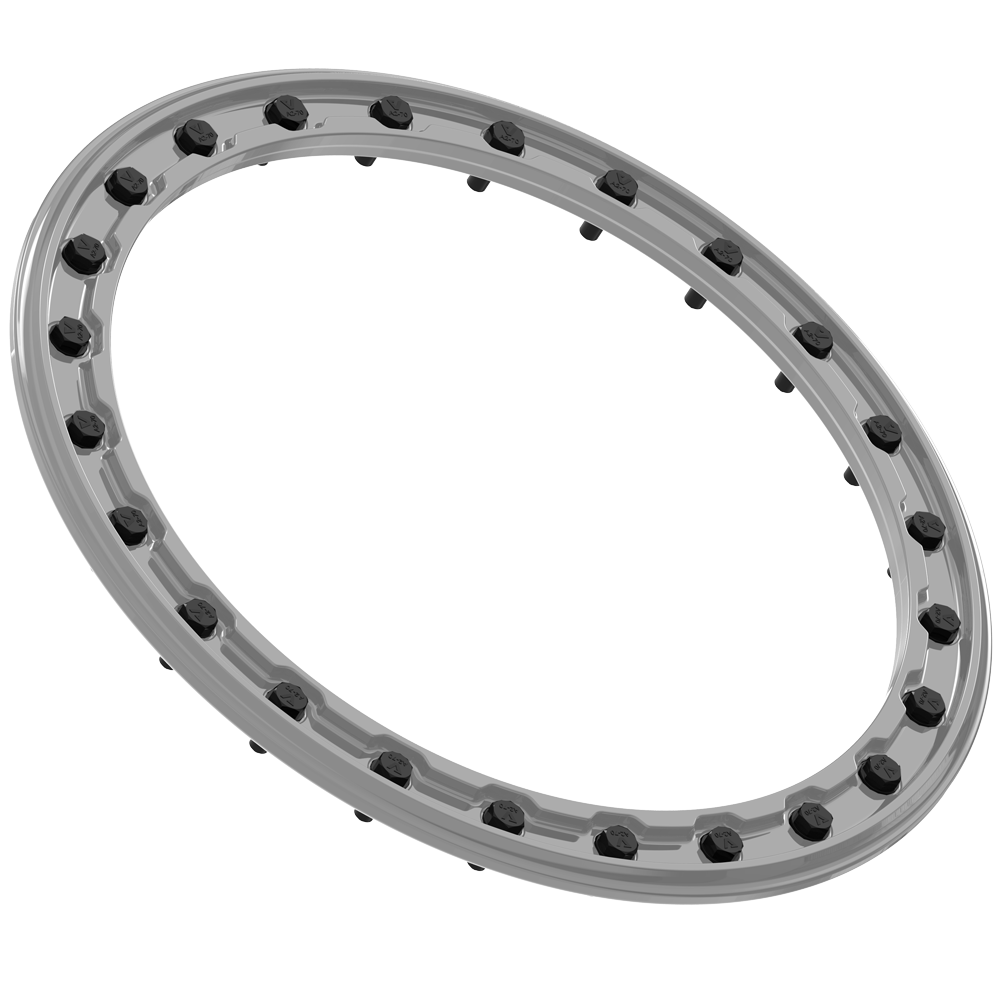

Segmented Tire Mold

Commonly used in the automotive industry, a segmented tire mold offers superior performance compared to traditional clamshell molds, particularly for producing intricate tread patterns and high-performance tires for various vehicles. The Tango UTV Tire utilizes a segmented mold.