UTV Wheels:

| STYLE | SIZE | OFFSET | LBS | BACKSPACE | MAX LOAD |

| V01 | 14x7 | +15mm | 11.90 | 4.59 | 1000 |

| V01 | 15x7 | +15mm | 13.23 | 4.59 | 1000 |

| V02 | 14x7 | +20mm | 13.45 | 4.79 | 1000 |

| V02 | 15x7 | +20mm | 14.77 | 4.79 | 1000 |

| V03 | 14x7 | +25mm | 12.02 | 4.98 | 1000 |

| V03 | 14x7 | -32mm | 12.46 | 2.74 | 1000 |

| V03 | 15x7 | +25mm | 13.45 | 4.98 | 1000 |

| V03 | 15x10 | +0mm | 14.60 | 5.00 | 1000 |

| V04 | 14x7 | +15mm | 13.23 | 4.59 | 1000 |

| V04 | 15x7 | +15mm | 14.33 | 4.59 | 1000 |

| V05 | 14x7 | +35mm | 13.83 | 5.38 | 1000 |

| V05 | 15x7 | +35mm | 14.82 | 5.38 | 1000 |

| V06 | 15x8 | +40mm | 16.72 | 6.07 | 1350 |

| V07 | 15x7 | +25mm | 16.50 | 4.98 | 1250 |

| V08 | 15x7 | +30mm | 16.86 | 5.18 | 1250 |

| V09 | 15x7 | +40mm | 16.96 | 5.57 | 1600 |

| V09 | 15x10 | +0mm | 19.90 | 5.50 | 1600 |

| V09 | 17x8 | +40mm | 20.40 | 6.07 | 1600 |

| V13 | 15x7 | +10mm | 17.20 | 4.39 | 1400 |

| V14 | 14x7 | +20mm | 11.10 | 4.79 | 1400 |

| V14 | 15x7 | +20mm | 13.10 | 4.79 | 1400 |

| V15 | 15x7 | +45mm | 17.50 | 5.77 | 1400 |

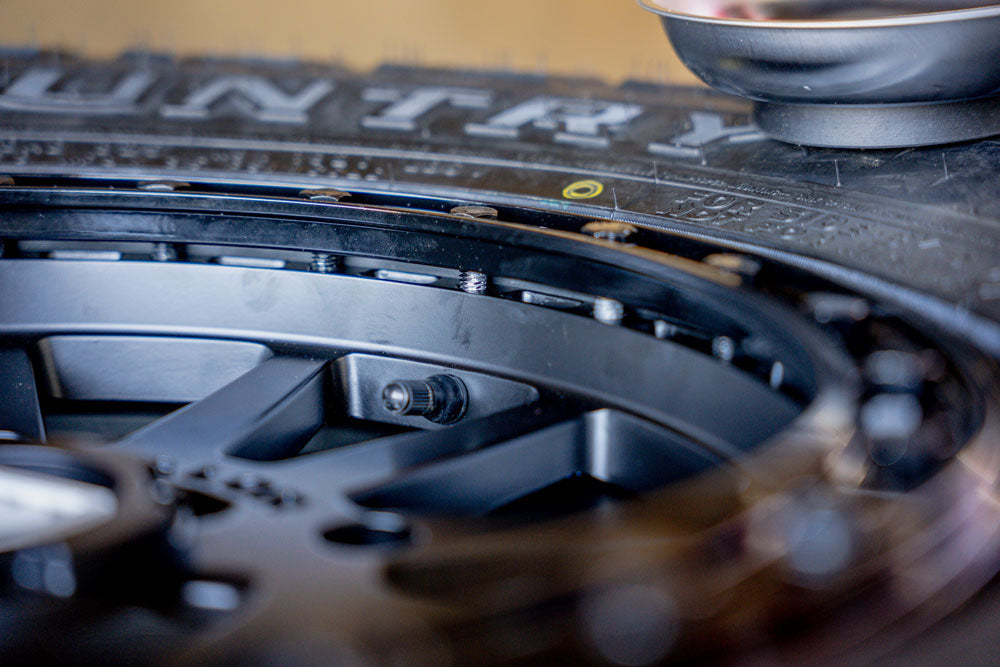

UTV Accessories:

| Hardware Kit | Fits: All Beadlock Wheels |

| VBR10 Beadlock Ring | Fits: All Beadlock Wheels |

| VBR20 Beadlock Ring |

Fits: All Beadlock Wheels |

| VBR30 Beadlock Ring | Fits: All Beadlock Wheels |

| Fits: V01-V08 | |

| VCAP1 Cap Black Out | Fits: V01-V08 |

| VCAP2 Cap | Fits: V09, V14, V15 |

| VCAP1 Logo Kit | Fits: V01-V08 |

| VCAP2 Logo Kit |

Fits: V09, V14, V15 |

UTV Tires:

| SIZE | WIDTH | WHEEL | RADIAL |

PLY

|

Duro |

| Alpha 30x9.50R14 | 9.50 | 14 | Yes | 8 | 65A |

| Alpha 32x10.00R15 | 10.00 | 15 | Yes | 8 | 65A |

| 10.00 | 15 | Yes | 8 | 55A/65A | |

|

Tango

|

TBA | TBA | TBA | TBA | TBA |