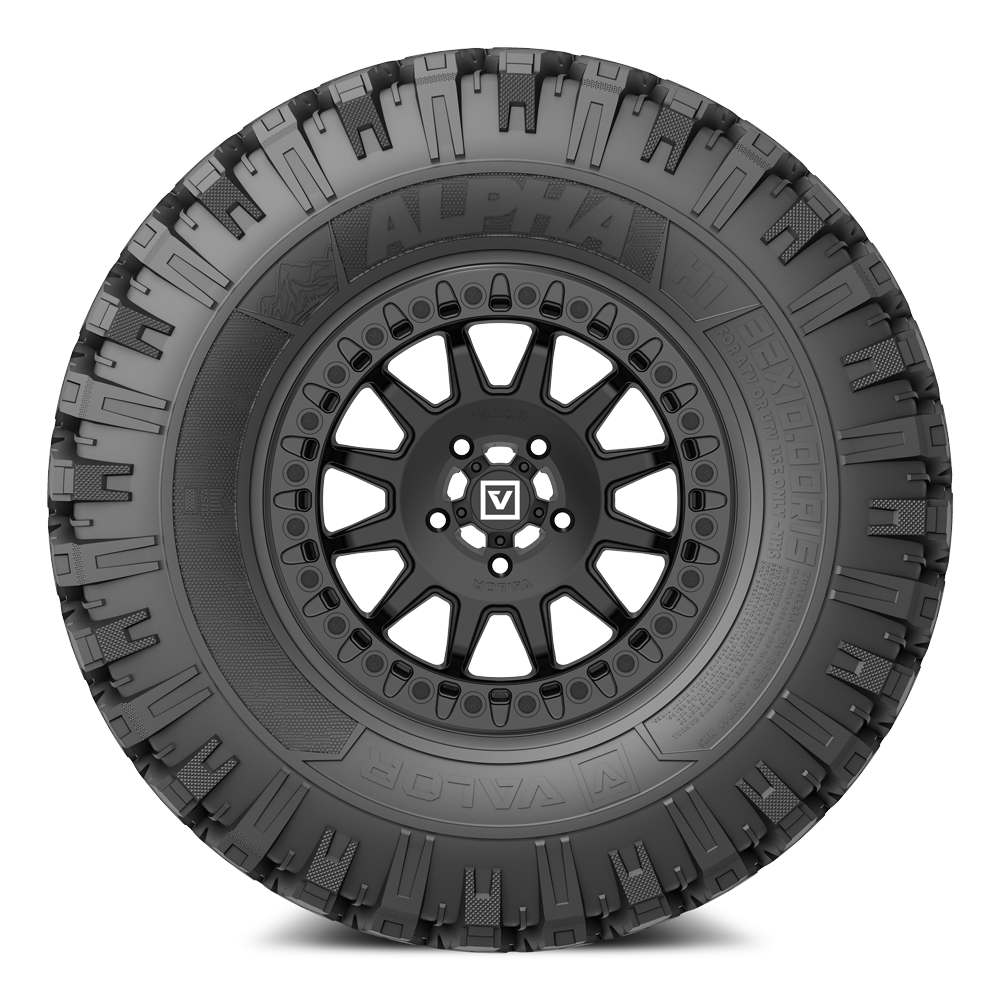

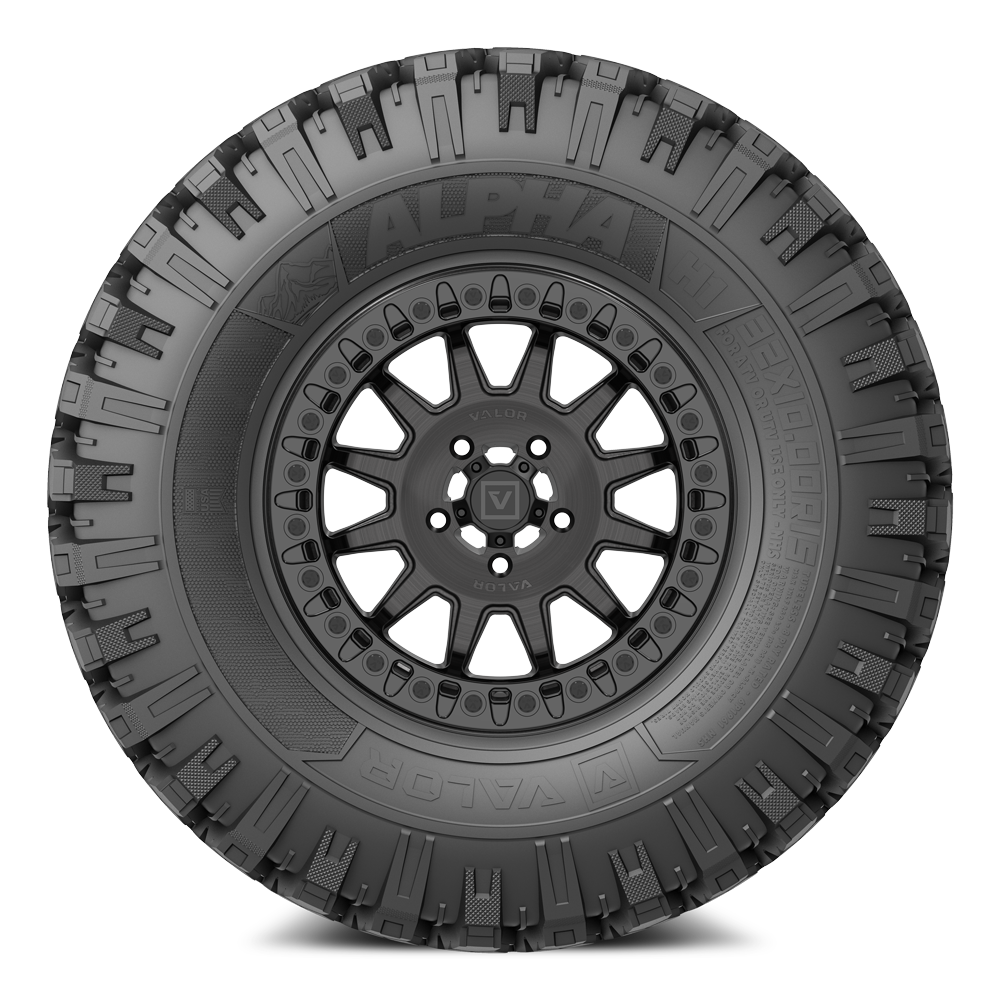

What Is Low Pressure Die Casting?

Low-pressure die casting is a casting process that uses pressure – rather than gravity – to fill molds with molten aluminum. Aluminum ingots are added via side chute. The holding furnace (A), located below the wheel cast, is heated until the ingots are liquid. The liquid metal (B) is forced upwards through a riser tube and into the wheel mold cavity (D). The pressure is applied constantly, sometimes in increasing increments (C), to fill the mold and hold the metal in place within the die until it solidifies. Once the cast has solidified, the pressure is released and any residual liquid in the tube or cavity flows back into the holding furnace for “recycling.” When cooled, the cast is simply removed.

Advantages of Low-Pressure Die Casting

Low pressure casting allows precise control during the filling process (B). Injecting the molten metal in this way reduces oxide formation (air pockets) and reduces porosity, ensuring consistency throughout the casting. Low pressure casting results in exceptional density in comparison to other casting processes (gravity/high pressure), as well as excellent strength and dimensional accuracy.

Other Casting Processes or Manufacturing Techniques

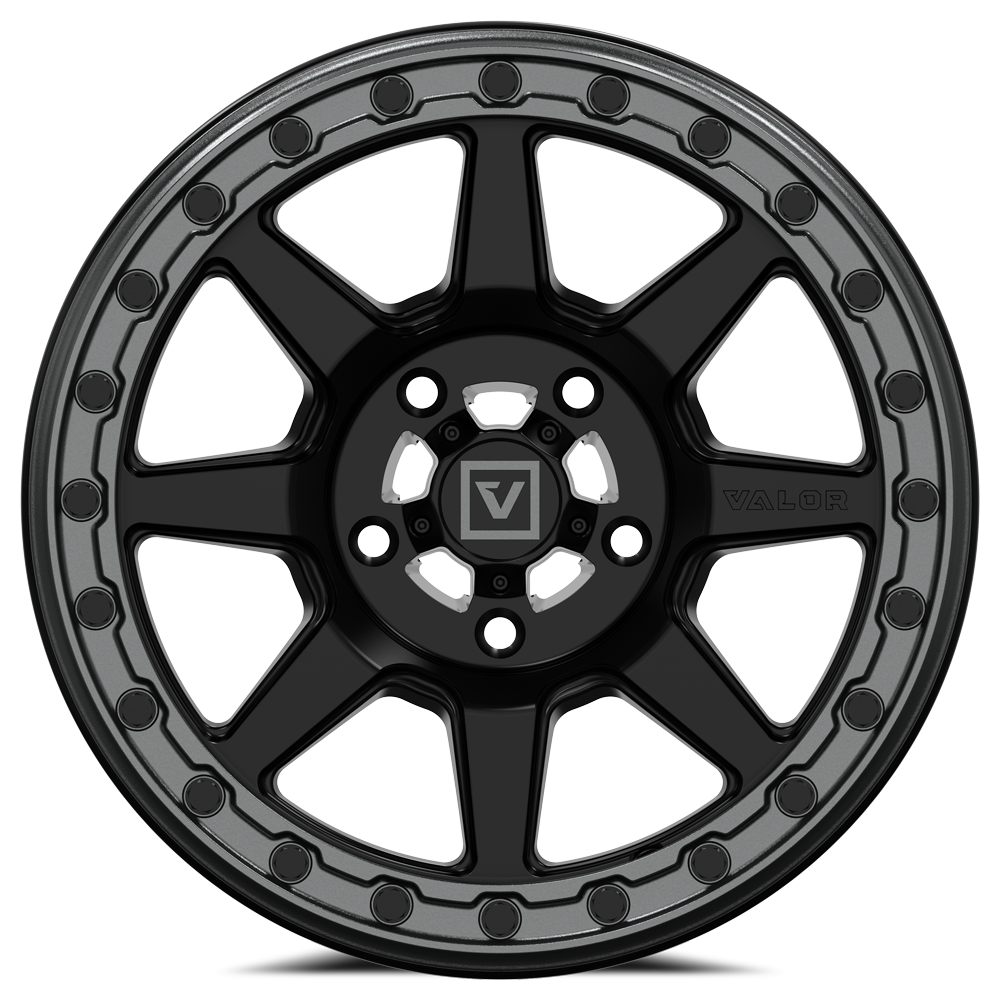

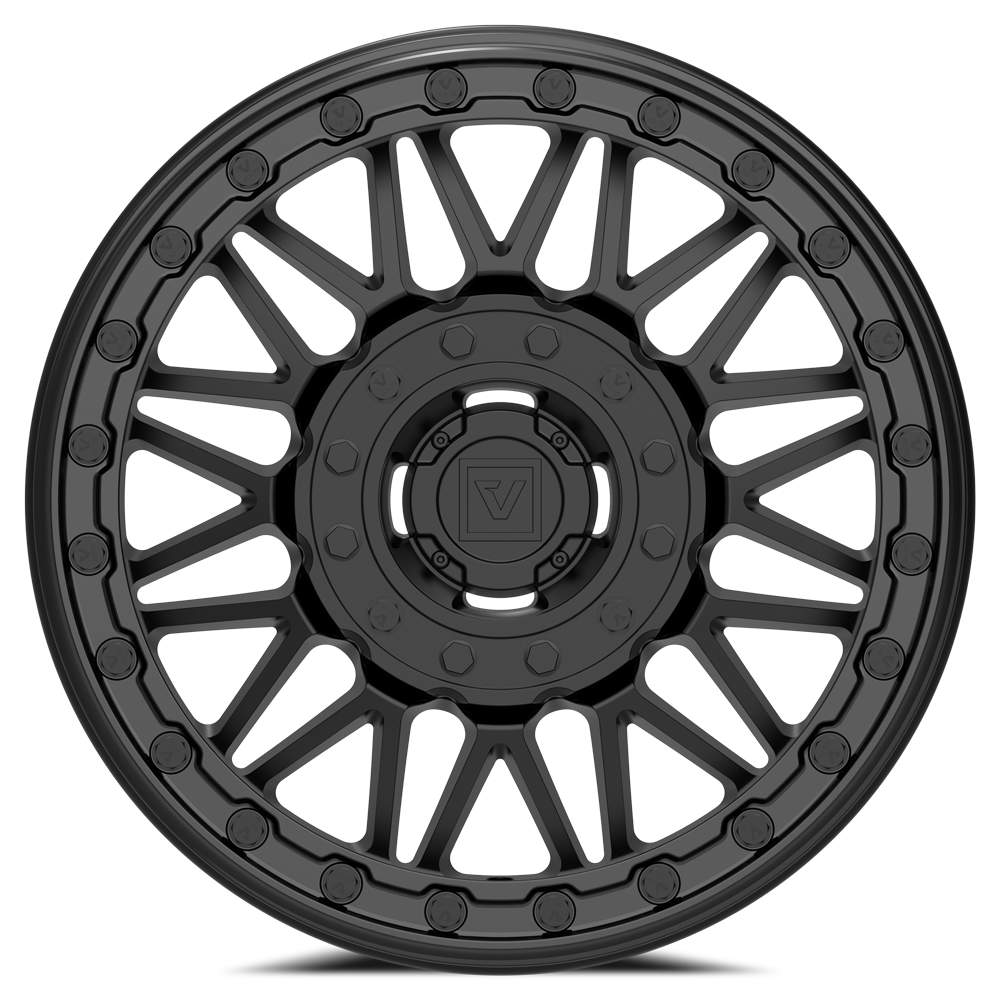

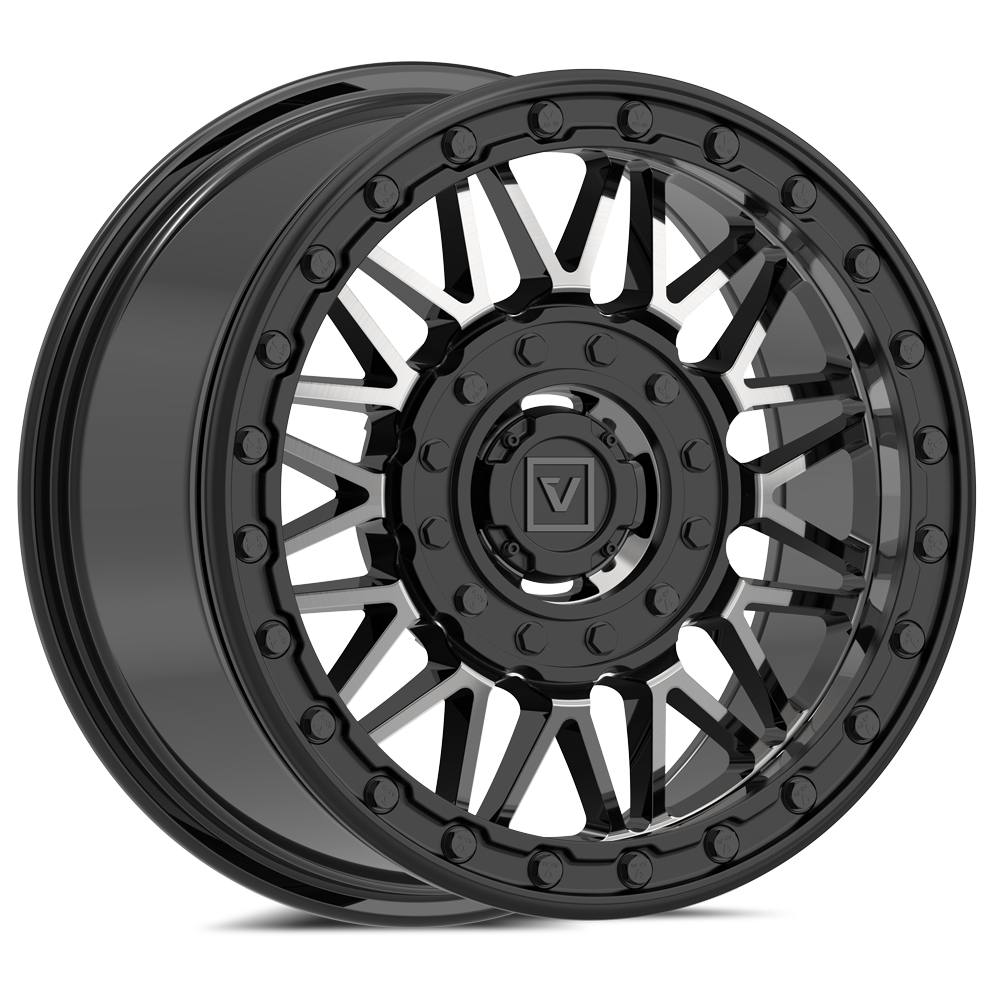

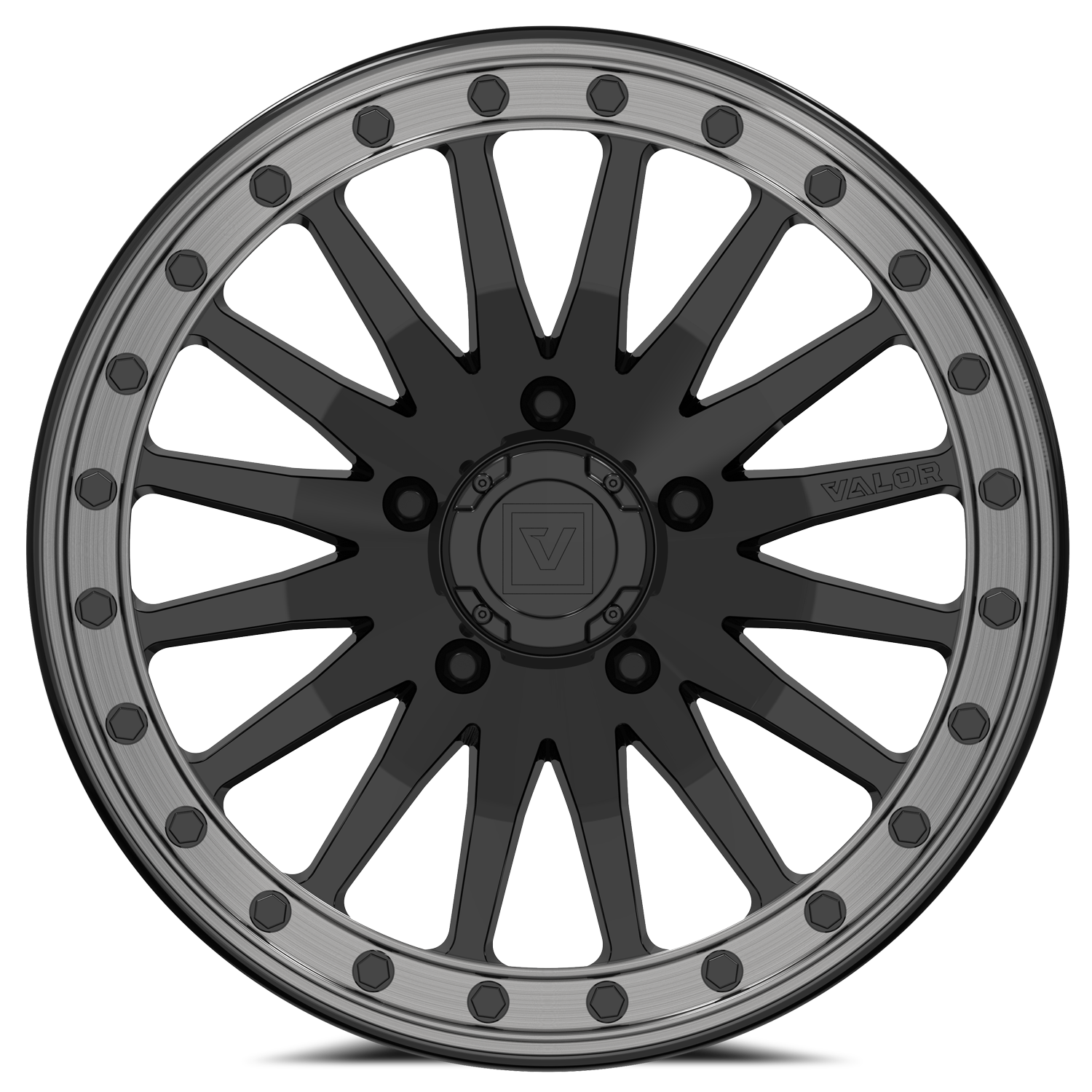

A low pressure casting process is what we use for all of our typical UTV wheel styles unless noted otherwise. We do have flow formed UTV wheels, which utilizes a unique manufacturing that blends traditional casting processes with attributes of forging, which produces incredibly lightweight wheels with improved strength. Learn more about flow forming and the pros and cons of various other casting processes / techniques by visiting our what is the best utv wheel post.