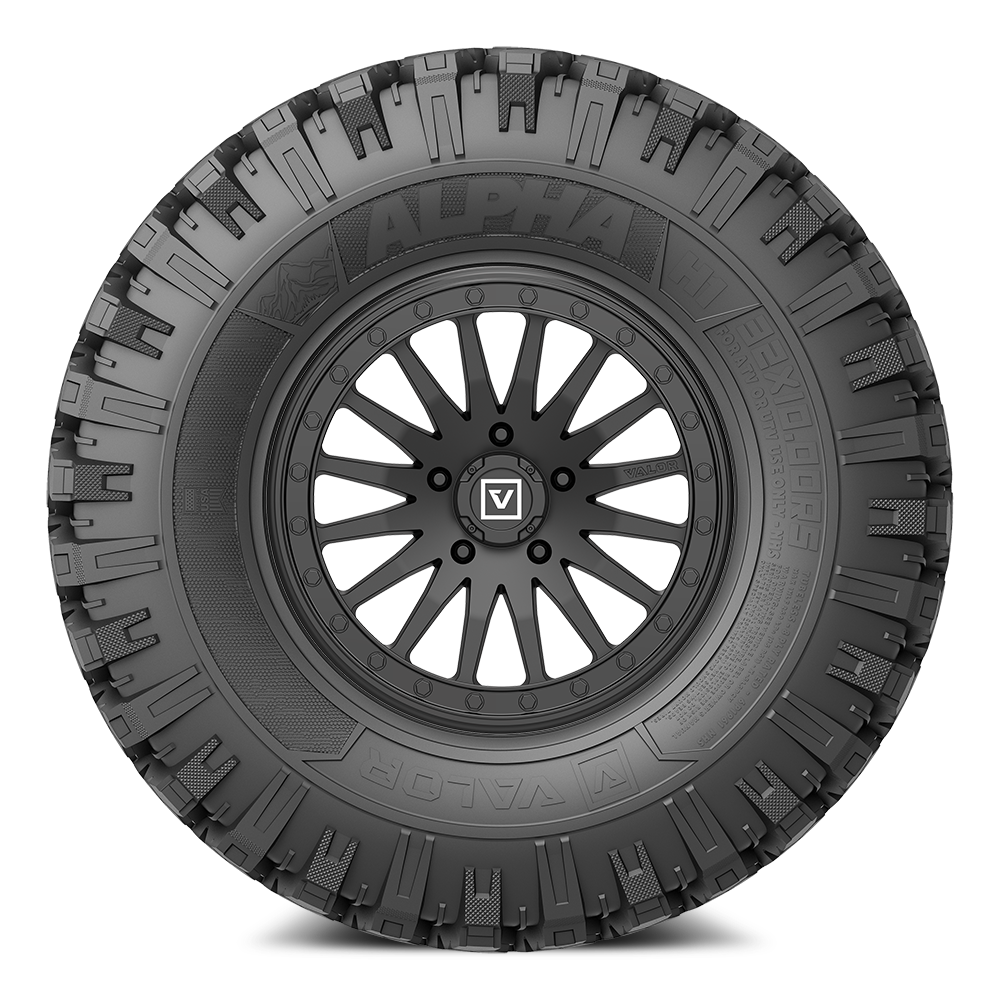

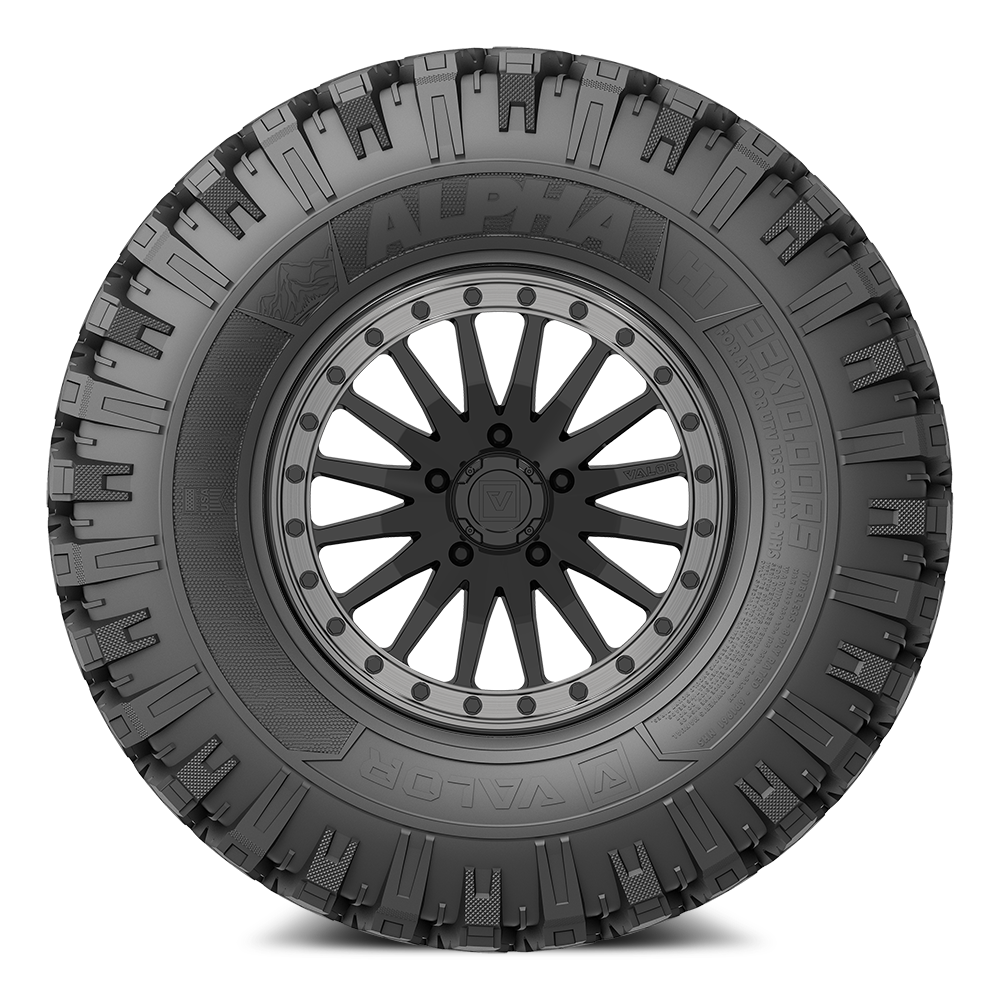

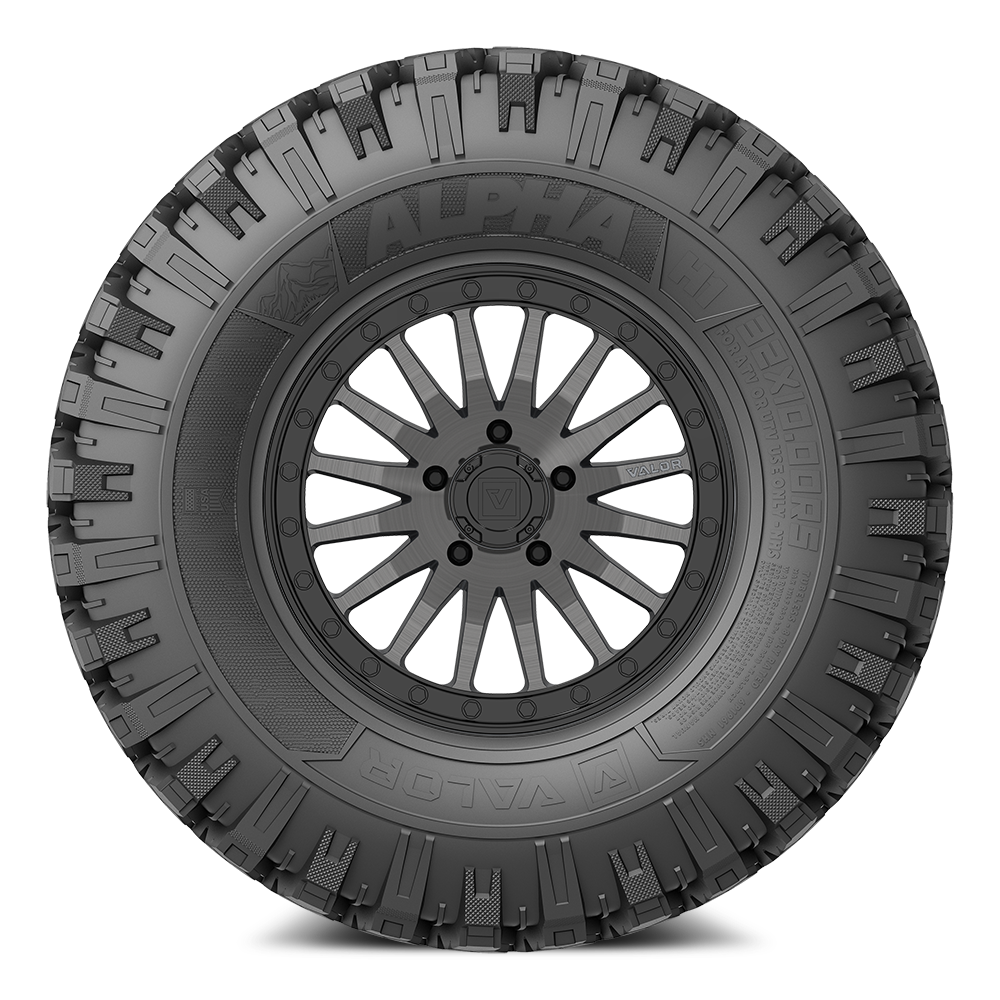

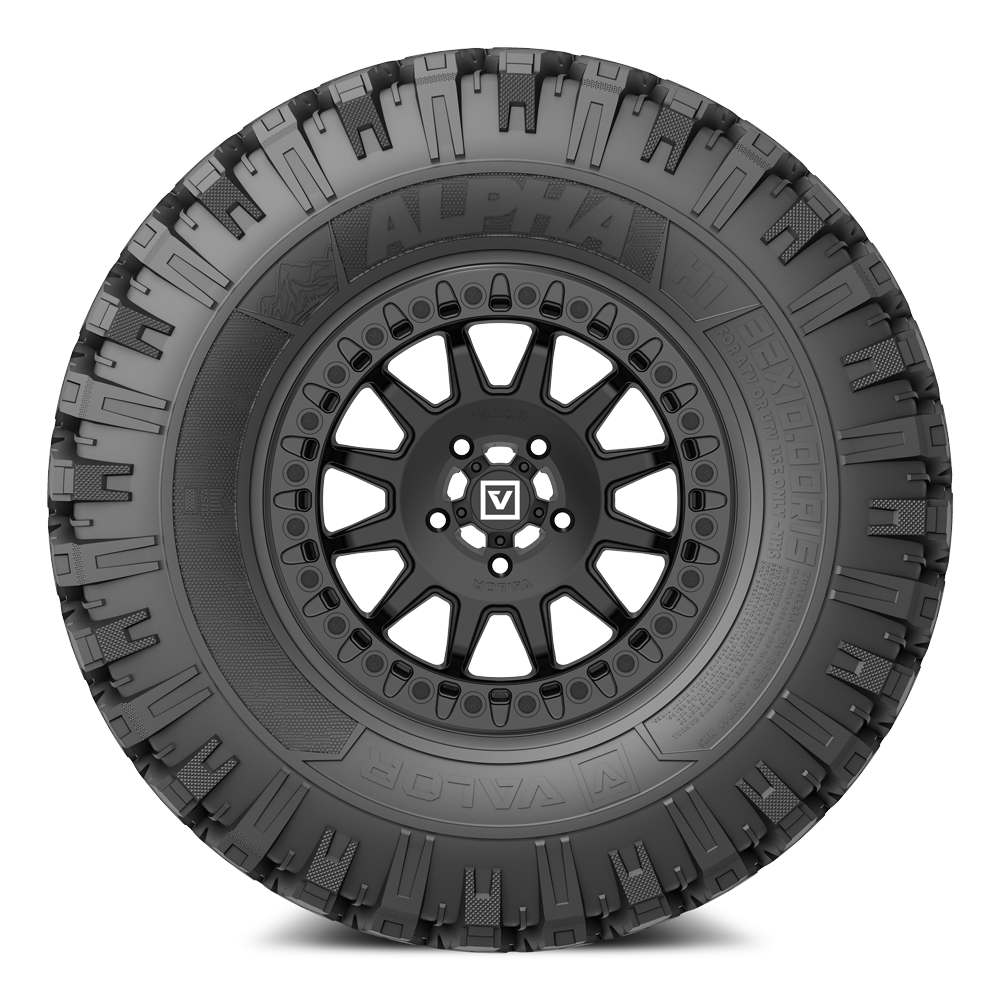

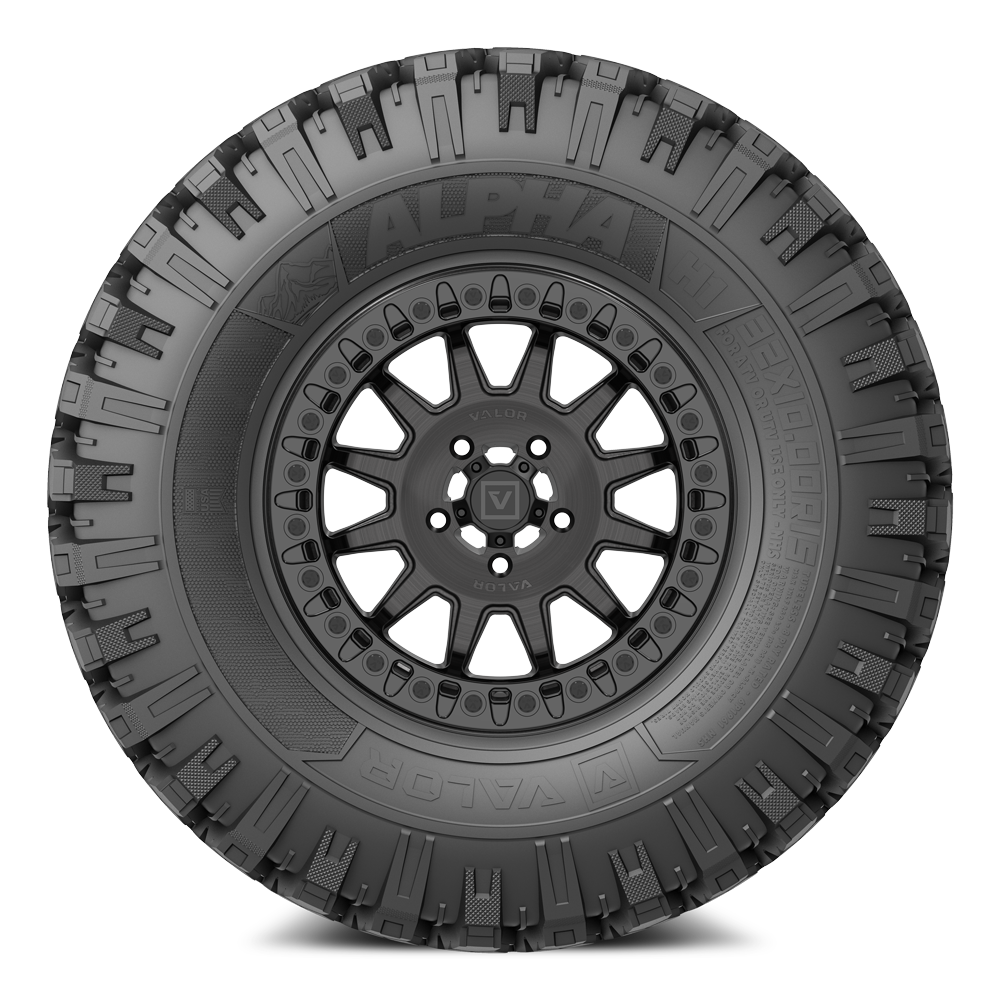

The Tango UTV tire by Valor Offroad benefits from several cutting-edge engineering and manufacturing techniques, including the use of a segmented mold during production. Commonly seen in the automotive industry, a segmented tire mold provides superior product advantages over traditional clamshell molds, particularly in producing intricate tread patterns and high-performance tires for various vehicles. These molds, with their modular design, allow for greater precision in tire design and manufacturing, leading to improved tire uniformity, durability, and performance.

Here's a more detailed breakdown of the benefits:

Enhanced Precision and Uniformity:

Intricate Tread Designs: Segmented tire molds allow for the creation of complex and detailed tread patterns, which are crucial for optimizing traction, handling, and performance characteristics of different tires, particularly those for high-performance UTVs and automobiles.

Precise Dimensions: The modular design (pieces) enables precise control over tire dimensions, leading to greater uniformity and consistency in tire shape and size, crucial for consistent specifications like overall diameter, overall width, tread performance, and significantly reducing defects.

Improved Balance: Segmented molds minimize green tire shifting during the vulcanization process, ensuring better balance and reducing the risk of vibrations and uneven wear due to overall uniformity.

Increased Durability and Performance:

Reduced Defects: The precision of segmented molds helps minimize the occurrence of defects like air pockets or uneven rubber distribution, resulting in dependable, higher-quality utv tires with improved durability compared to tires produced in clamshell molds.

Extended Mileage: In addition to consistent tire dimensions, segmented tire molds offer even tread wear (uniformity), and optimized tread patterns can lead to extended mileage and longer tire life, allowing customers to get the very most out of each set of tires before having to replace them.

Enhanced Tread Adhesion: Segmented molds can utilize high internal air pressure during curing, promoting superior adhesion between the tread and casing, making tires more resistant to breakdown over time, particularly at higher temperatures.

Specialized Applications: The flexibility of segmented molds allows for the development of tires for specialized applications like sport UTVs, where high-performance models like the Polaris Pro R, Kawasaki KRX H2, and Can-Am Maverick R are generating 200+hp.

The Tango UTV Tire is on the razor's edge of engineering and manufacturing techniques, offering automotive-grade performance and reliability, in a lightweight all-terrain utv tire design for all makes and models of UTV, SXS, and ATV. Segmented tire molds provide a significant advancement in tire manufacturing, offering a combination of enhanced precision, performance, and durability compared to traditional methods. Segmented molds are particularly well-suited for producing tires for a wide range of vehicles and applications, from passenger cars to agricultural equipment and UTVs.

Want to learn more?

Other types of tire molds:

Puzzle Molds: This design prevents unwanted rubber formation, particularly during the curing phase of production, and improves the exterior quality of your tires. Gaps between segments are used in the mold's venting system to exhaust internal gases. Complex tread pattern molds are more difficult than puzzle molds, and maintaining consistent dimensions during production can be an issue. These are highly suitable for ultra-high-performance passenger cars. Puzzle molds are rarely used in the manufacturing of UTV tires.

Wave Parting Molds: These molds are manufactured by 5-axis machining using specialized CAD technologies for precise manufacturing, resulting in optimal tire performance and exterior quality. In particular, this mold type excels at preserving complicated geometric tread patterns. Wave Parting molds are rarely used in the manufacturing of UTV tires.

Steel Engraved Molds: These molds have direct pattern engraving made by advanced 5-axis machining technology. You get outstanding thermal stability, corrosion resistance and wear resistance because of using chromium enriched steel. Specialized CAD/CAM systems with integrated sipe blades are used to make precise tread patterns. Perfect for heavy-duty trucks and earth movers. Steel-engraved molds are rarely used in the manufacturing of UTV tires.

Aluminum Cast Molds: Aluminum cast molds use specialized QC 10 alloys that provide you with better thermal conductivity and eliminate the need for extensive water lines. Because of their natural oxide layer, these molds need less maintenance and no additional corrosion protection. Aluminum cast molds provide excellent machining characteristics. Annual repairs are required because of deformation caused by the repeated opening and closing operations. They are lightweight and have outstanding heat transfer attributes. Aluminum cast molds are very commonly used on UTV tires and represent the majority of tires on the market.

Retread Molds: Retread molds have rigid construction, with precise tread designs, which vulcanize uncured rubber onto buffed casings. You can choose between two primary systems for molds—mold cure and pre-cure technology. In mold cure, you put non-vulcanized rubber right on buffed casings, and in pre-cure, you use pre-vulcanized treads with cushion gum bonding. These specialized molds have incorporated tread designs for particular applications like recreational vehicles and long-haul trucking. Retread molds are not used in the manufacturing of UTV tires.