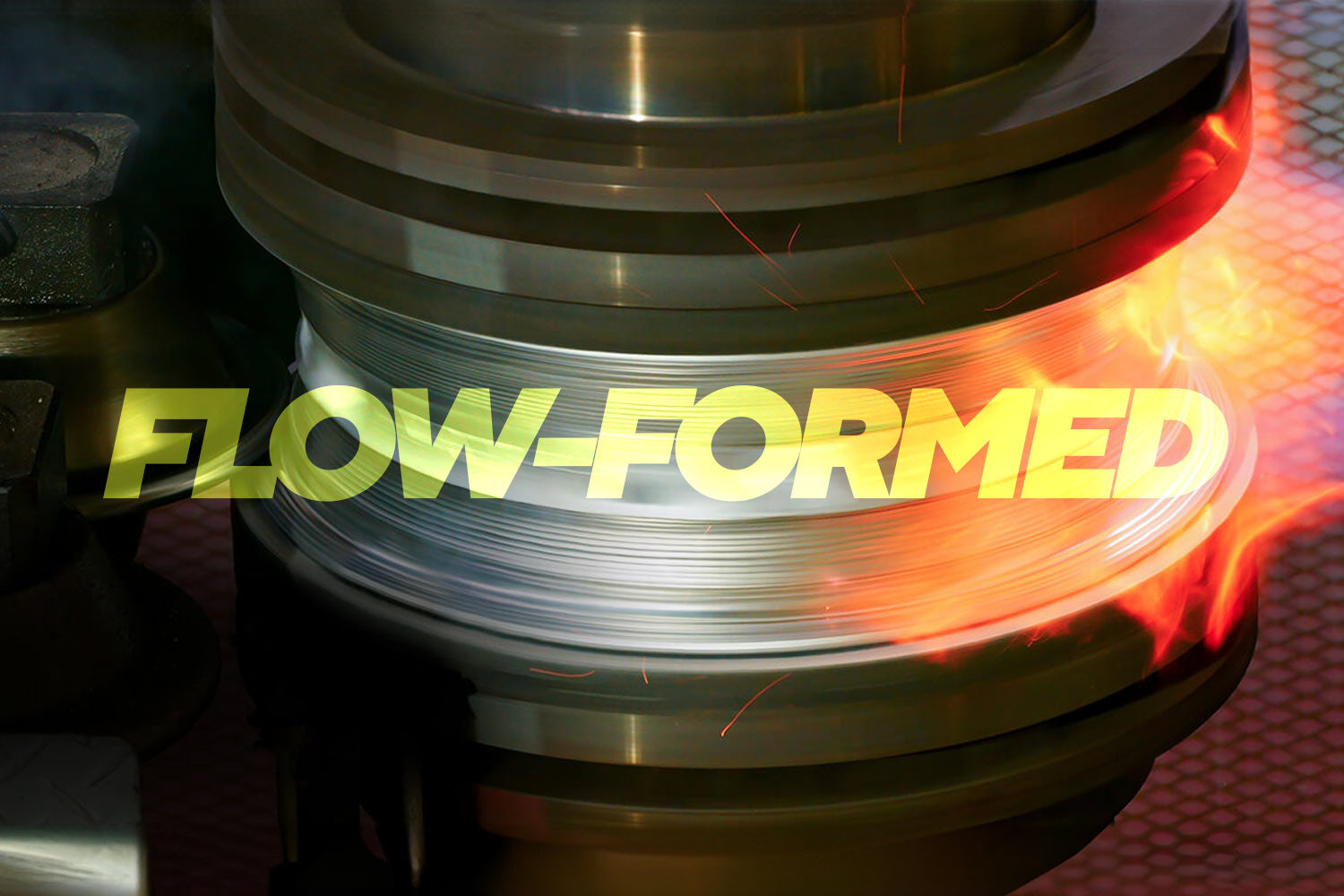

Flow forming is an advanced manufacturing process that gives cast aluminum wheels the strength and quality of forged wheels. It uses hydraulic rollers and high pressure to shape the inner rim, forcing the aluminum to match a steel tool. This method stretches a small amount of aluminum along the tool to form the rear barrel, using less material. As a result, flow-formed wheels are stronger, lighter, and more precise than those made with traditional casting.

- 1: The wheel face, including the center spokes and outer lip, is made using low-pressure die-casting. The rear barrel is not cast at this stage but will be formed later during the heated rotary forging process.

- 2: The rear barrel of the wheel is heated, and hydraulic rollers apply pressure to spread the aluminum. With even pressure, the barrel is shaped using a precise program and a rotating drum die.

- 3: The hydraulic rollers keep applying pressure until the barrel reaches its final width. At the end, the rear lip of the barrel is formed.

Flow forming offers many benefits. It improves the strength of aluminum and uses the material more efficiently. Compared to standard UTV wheel casting, flow-formed wheels are more precise, have a better surface finish, are harder, and have a better grain structure. This process makes UTV wheels both higher quality and more efficiently produced.

Grain Structure Matters

CNC machining is typically performed on a pre-worked (hardened) billet that already has grain flow. We use this process in our billet beadlock rings.

Cast UTV wheels do not have uniform grain structure, flow, or directional strength. During the casting process, slurry is poured into a mold, and as this slurry cools, dendrites form, eventually turning into grains. These grains are not uniform, as some may be small, large, coarse, and/or fine, which results in grain boundary voids. When there are voids in a manufactured component, this means that that component will have very little impact or fatigue resistance.

Flow forming aligns the grains in the aluminum to maximize strength, giving the wheels excellent resistance to fatigue and impact. By stretching the grain structure lengthwise, this process makes the aluminum much stronger. The direction of grain flow affects how the material handles stress and fatigue.