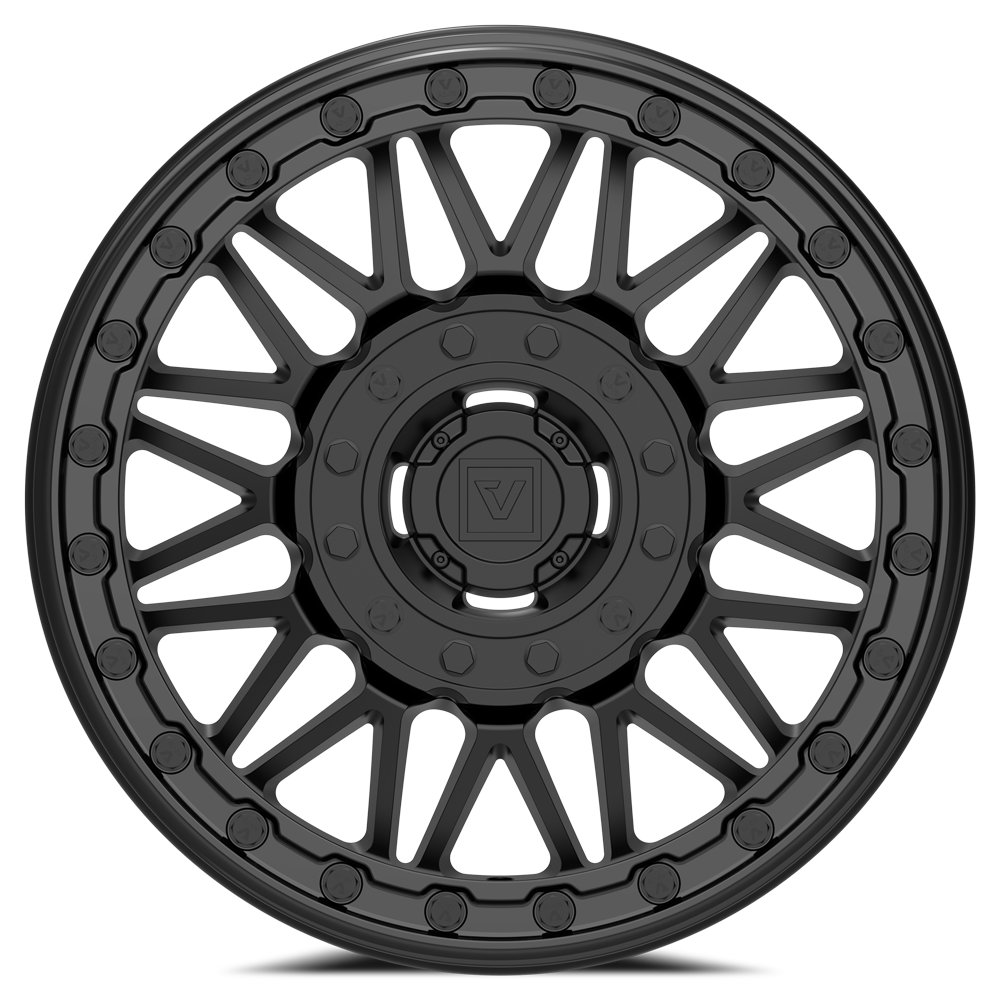

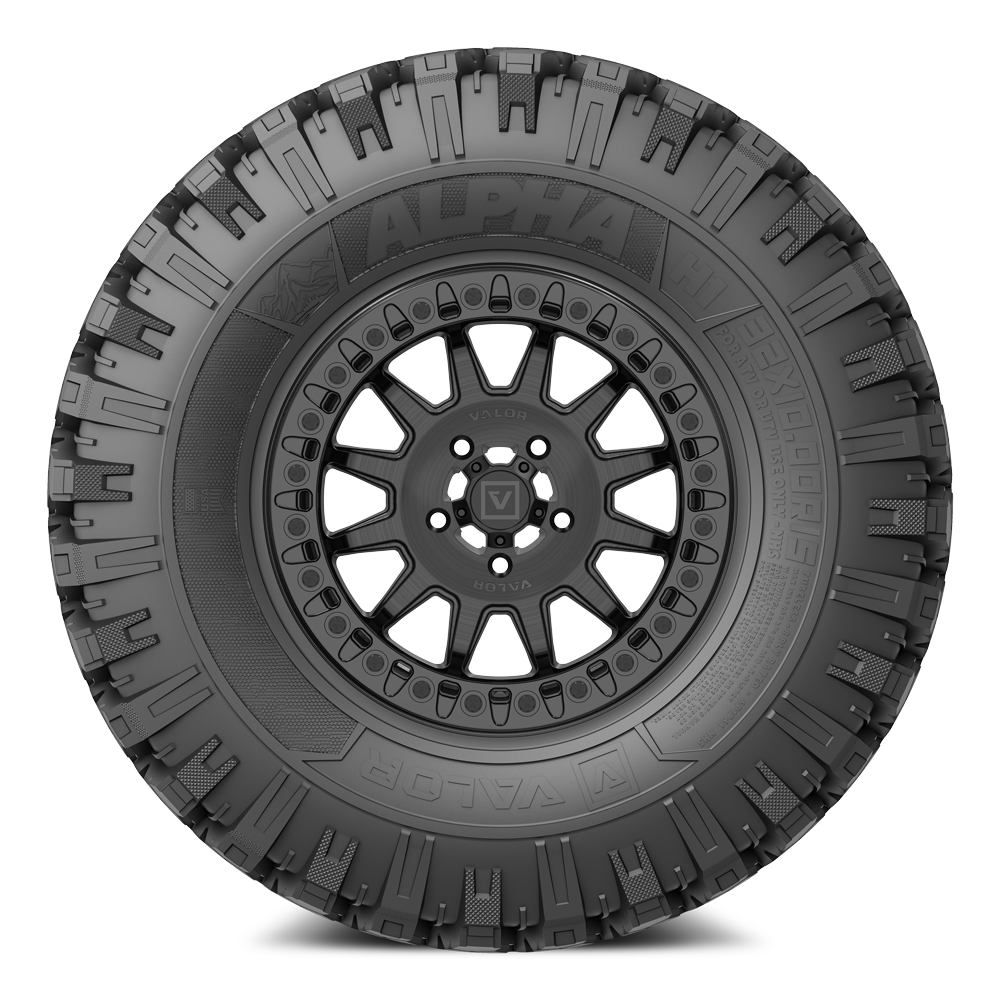

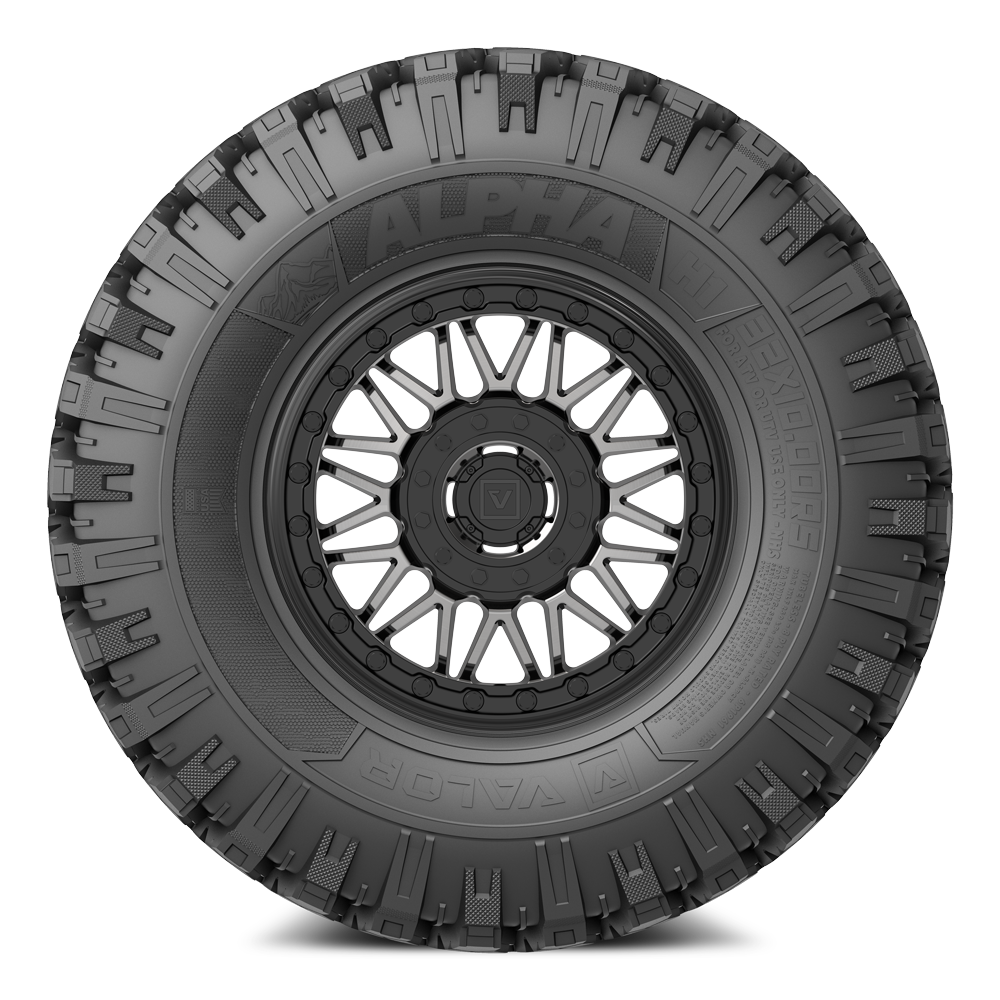

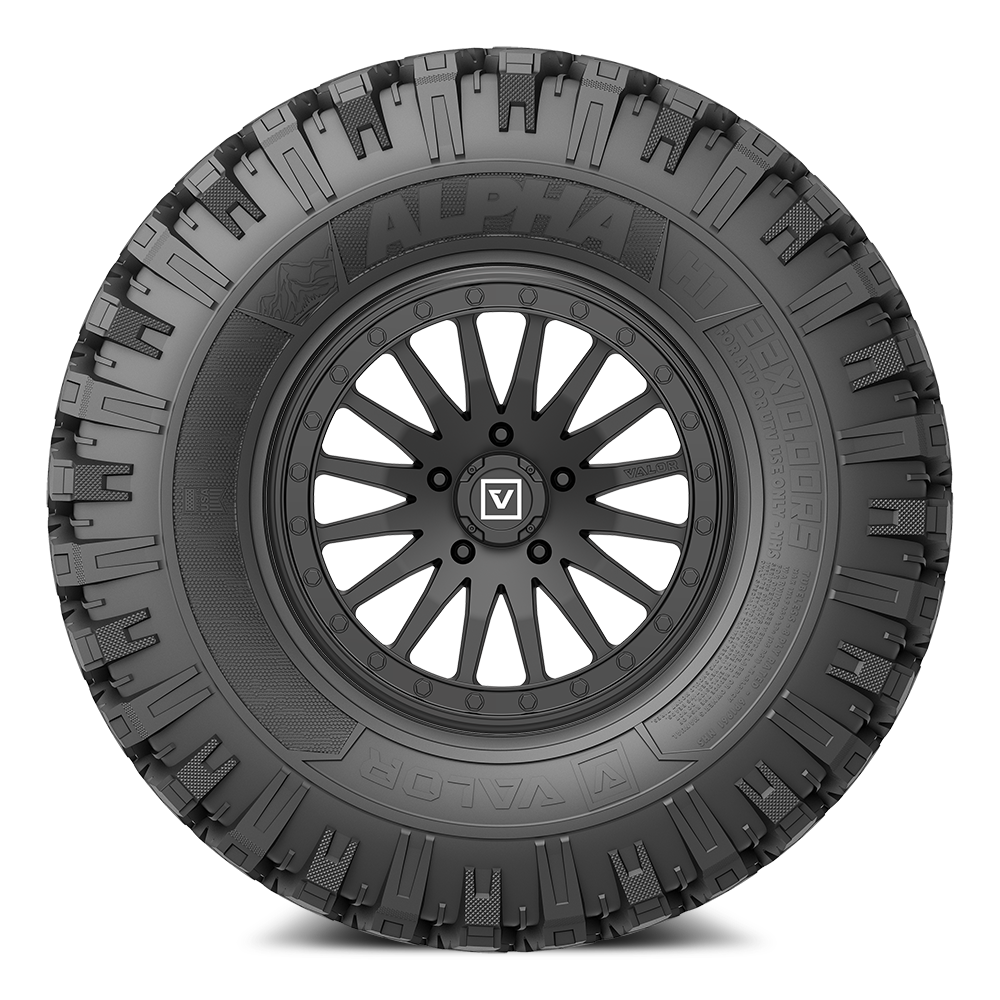

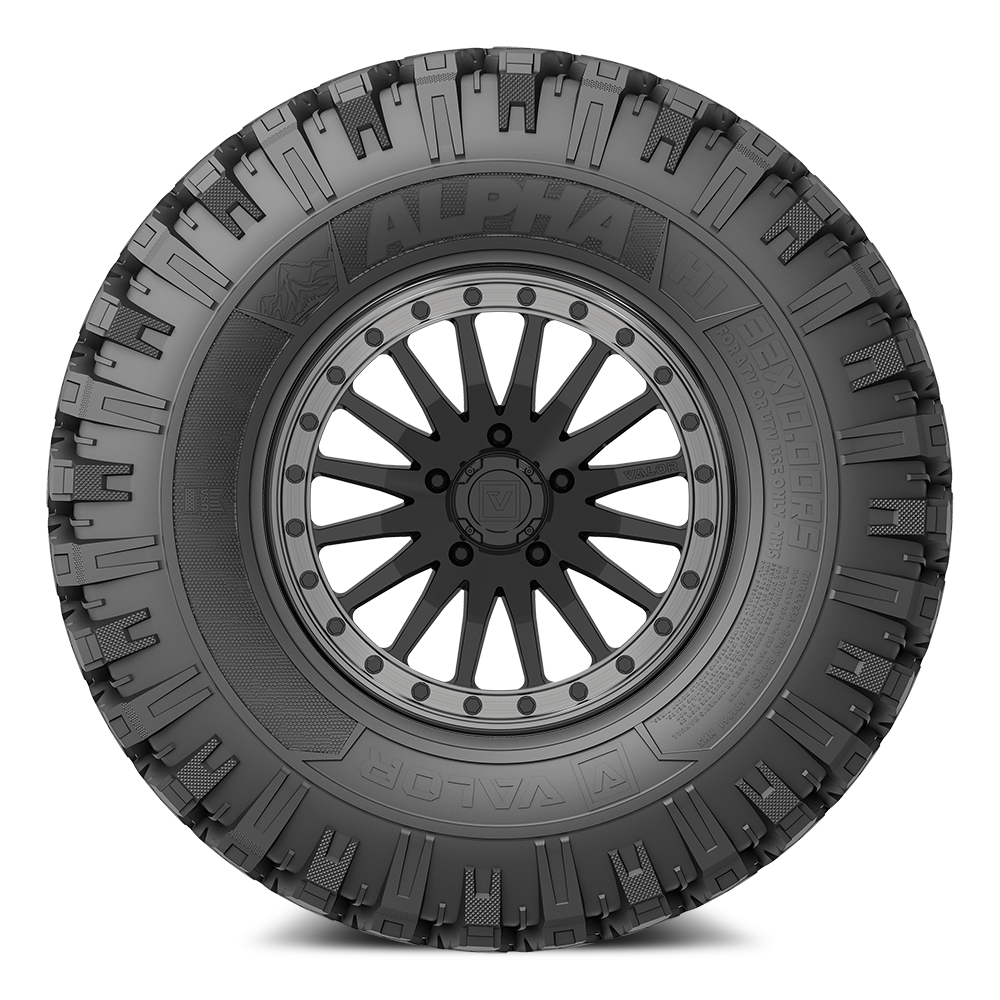

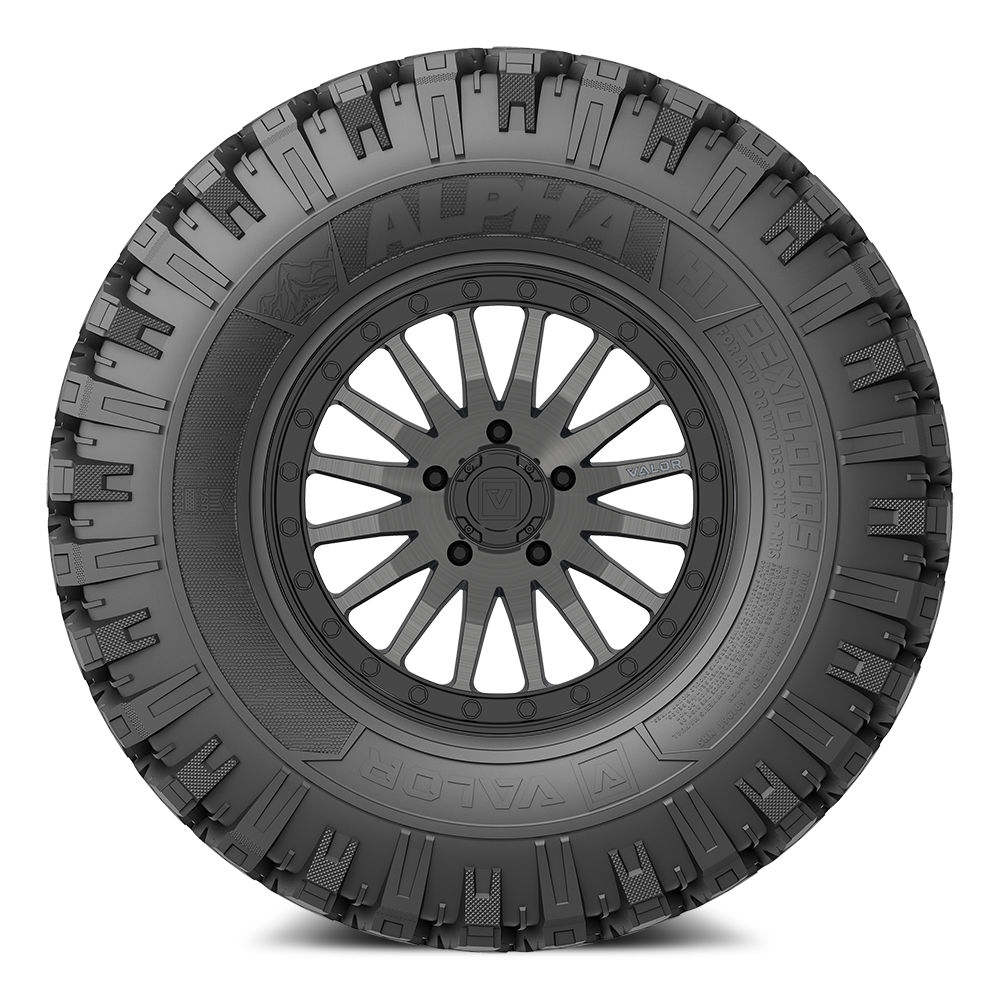

Your guide to mounting and installing your new Valor Offroad UTV Beadlock Wheels

- Beadlock wheels are intended for off-road use ONLY.

- Only properly trained professional tire & wheel installers using OSHA approved safety cages and safe tire mounting practices should mount and inflate tires.

- Each bolt MUST be checked and tightened for correct torque specifications using star pattern.

- Never exceed 25 pounds to seat inner tire bead.

- You must frequently inspect bolts and hardware to ensure bolts are correct torque spec. We recommend retorquing before every ride.

- Only use Valor Offroad approved beadlock wheel hardware and replace hardware if bolts are in any way damaged or worn.

Inventory Check

- You're going to need four (4) beadlock hardware kits. These are the rectangular boxes located in the bottom of your Valor Wheels box. Each hardware kit should enclose twenty (24) M8x25mm A2-70 stainless steel bolts and twenty (24) A2-70 stainless steel16x1.5mm washers.

- 13mm socket

- Hand ratchet

- Torque wrench to ensure you have the correct foot pound torque on all of your bolts (you'll also need this tool for installation of wheels on vehicle).

- (Optional) Anti-sieze lubricant (like Permatex) for mounting hardware.

UTV beadlock wheel installation at home:

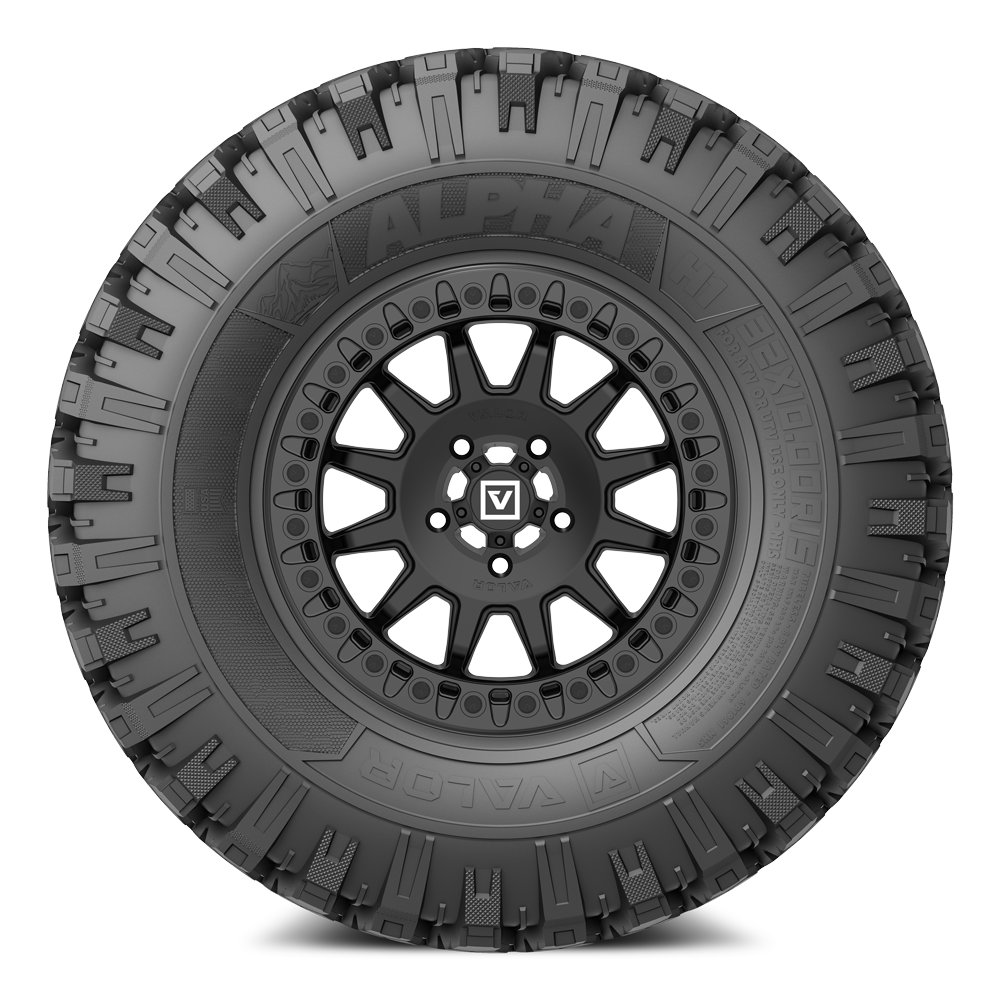

If you have directional (asymmetric) tires, make sure you're paying attention here so your tires/wheels are facing the right direction. Not sure if your tires are directional? Look for an arrow on your tire sidewall which will point toward the front of your vehicle (or how the tires should rotate in motion). Remember with directional tires that you'll have to mount your passenger side wheels on one side of the tire, and drivers side wheels on the other to maintain true directional. If your tires do not mention a direction, or the tread does not flow in a particular direction, more than likely you have a non-directional tire and you can mount your wheels on either side of the tire.

Mounting Tire

Once you get the rear bead set, you're going to need to prop the wheel up on a much taller surface so that the tire can freely hang and pull the front tire bead tight on the wheel face. We like to use a five gallon bucket (Home Depot or Lowes) for this step because EVERYONE has these buckets laying around and they provide just the right height to make the job easier. If you feel the bucket is a little wobbly, fill it with rocks or something heavy.

Some tires have a mark on the sidewall near the bead that refers to the lightest spot on the tire. Make sure this mark (yellow circle on the tire we're using) is lined up directly under the valve stem of the wheel. The yellow circle or dot can help to balance your wheel and tire assembly so that its lightest point of the tire (the yellow circle) is matched up with the wheel's heaviest point (valve stem). The yellow dot indicates where the manufacturer has identified the lightest spot on the tire.

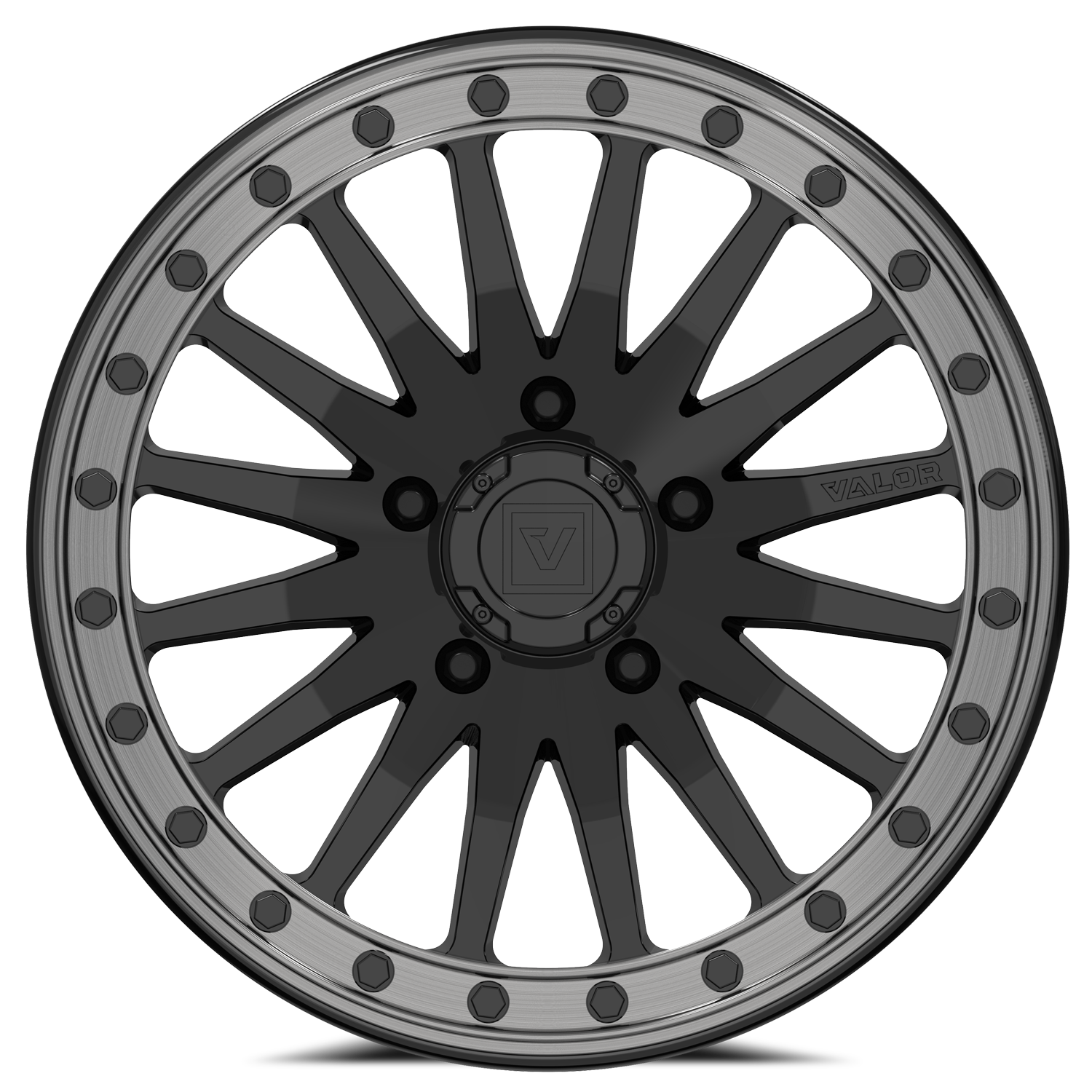

Assembling Beadlock

Once you have all of your bolts and washers started, you'll want to utilize a star or plus (+) shape pattern as you hand-tighten to snug. Select the bolt directly across from your first bolt and then criss cross your way across the wheel in a star patten until all of the bolts are hand tightened snug. Grab your hand ratchet and repeat the star pattern again, tighten all of the bolts/washers again to snug. Tightening bolts by hand and then with hand ratchet will prevent over tightening any of the bolts, especially when the ring has not been completely set.

Next up, grab your handy torque wrench and set the foot pounds to 18 for the next tightening. By slowly adding pressure to each bolt, your rings will connect with wheel and remain perfectly flat to correctly hold your tire bead in place. DO NOT EXCEED 18 ft pounds when installing your beadlock rings!

During third tightening with torque wrench, tighten your bolts to 18 ft pounds until you hear an audible "click" sound on your torque wrench. If you're forgetful, mark every finished bolt with chalk so you know which bolts have been tightened and which ones you have left to do. The fourth and final tightening is a double check, making sure each bolt has a clear, audible click from the torque wrench. It's better to be safe so don't fret if you go over each bolt a couple of times to hear that trusty "click" sound.

Heading out right away for a ride? Air up your wheels to the correct tire specification(s) and using your 1/1 soap/water concoction you used to lubricate the tire, spray all over your wheels where ring and tire connect. If your wheels are leaking air, you'll immediately see bubbles which will require you to dissemble and start over to ensure you made a good connection from bolt to ring to tire/wheel.

TLDR;

- Take your time. Don't be in a rush.

- Mount inner bead over the backside of wheel.

- Slide the outer tire bead on and center the tire.

- Line up low spot on tire with valve stem. Low spot typically has a colored dot or mark on sidewall near lip protector.

- Place ring and align the bolt holes.

- Apply anti-seize to the threads of each bolt. Anti-seize is your friend, use it.

- Start bolts by hand to avoid cross threading.

- Using a star pattern, tighten each bolt a few turns at a time to ensure even pressure on the beadlock ring.

- Using torque wrench, tighten the bolts in star pattern to 18 ft lbs.

- Do a final round of tightening to ensure ALL bolts give click sound on torque wrench.

- Lube backside inner tire bead.

- Inflate the tire to seat the inner bead onto the wheel. DO NOT exceed tire manufacturer’s recommended maximum pressure for seating the beads. You will hear an audible "pop" when tire bead seats on wheel.

- Re-torque the ring bolts after the first 50 miles, and after each subsequent 200 miles.

- A few drops of dish soap in water can be sprayed to detect air leaks and ensure safe ring/tire seating.

- Over tightening the beadlock bolts or using an extra thick tire bead without a spacer can cause immediate stress points which can lead to leaks and/or complete wheel and tire failure. If the beadlock ring bends inward (taco) toward the center cap or does not sit absolutely flat, DO NOT INSTALL ON VEHICLE.

How to install wheels to your UTV the correct way

You've assembled your new UTV beadlock wheels, now its time to install them on your machine. We STRONGLY recommend you have a professional install your wheels and/or tires. If you do not know of a reliable dealer or technician near you, call us and we can help locate one for you. If you insist on mounting your own wheels, you MUST follow all steps below to ensure a proper and safe installation:

- First step is to make sure you have the correct installation kit (lug nuts). Not all lugs are interchangeable and if you're planning to run any Valor Offroad wheels, your OEM stock lugs WILL NOT WORK. You must purchase a kit from our Installation Kits. Not sure what kit you need? Check out our Fitment Guide.

- Next, you're going to want to find flat ground to jack your vehicle off the ground. Because UTVs and ATVs do not come with an OEM parking/emergency brake, finding flat ground is your best bet for a safe start.

- Before you start jacking your vehicle up, use a quality torque wrench to loosen the lugs on the wheel while all four tires are still on the ground. This will ensure you're not wrenching on a stuck lug in the air or while the tire is spinning. Getting the lugs loose ensures a safe swap while vehicle is up on jack or rack.

- Using a floor jack or emergency jack from your vehicle, begin to raise your vehicle up enough where the tire rotates freely. Are you plus-sizing your tires (increasing overall diameter)? You're going to want to factor in more room off the ground to allow for new, larger tires.

- Once your vehicle is safely jacked up and wheel and tire are ready to be removed, unscrew all lugs using your fingers or socket. If you need to use the torque wrench, you didn't loosen them enough while on the ground. Stop what you're doing and go back two steps.

- After you swap out your wheels and tires, finger tighten your new spline lugs as far as you can.

- Using the socket only (not attached to torque wrench), tighten lugs down as much as you can using a star pattern (view diagram below).

- Lower the vehicle just enough to where the tires make contact with the ground and prevent the wheel and tire from spinning.

- Using torque wrench, tighten each lug to vehicle OEM spec. Not sure what your OEM spec is? Contact your local dealer or visit your vehicle's owners handbook.

- Completely lower the vehicle down to the ground and using the torque wrench again, ensure all lugs are to spec again using star pattern below. You'll hear an audible noise when lugs are correctly torqued.

HOW TO TIGHTEN LUGS

But wait, there's more!

You MUST re-torque your lugs to OEM spec after no more than 20 miles. This applies to your daily driver, towing trailer, lawn mower and especially your UTV, SxS or ATV. Want to learn more about what happens when you decide to skip the retightening step? Check out our Why you should tighten your lugs post.

Warning Signs:

How do I know if my lugs are loose?

- Your gut is your best bet to prevent a catastrophic accident. If anything feels "off" with your vehicle, don't wait until you get home, pull over immediately and do a thorough inspection. Look at irregular stud length or abnormal wear on any parts.

- A wobble in your steering wheel is the first dead give away that something is up with one or more of your wheels and/or tires. You'll feel a tug on your steering wheel that will make it wobble back and forth. This may be a subtle wobble but follow step one above and always trust your gut. The wobble may be as simple as you threw a tape weight on your truck wheels or that your alignment is out of whack, but it's always better to be safe than sorry.

- Smoke. If you see or smell smoke, you've already hit the point of no return. Pull over IMMEDIATELY.