In order to understand how your wheel weight affects your vehicle performance, you need to understand how a vehicle is engineered. The weight of your UTV can be divided into three different categories:

-

Sprung Weight / Mass

The sprung weight is the total weight of all parts on the vehicle that is supported by the vehicle's suspension. Some examples are the engine, exhaust system, body and interior parts.

-

Unsprung Weight / Mass

The unsprung weight is the total weight of parts that are NOT supported by the vehicle’s suspension. We’re talking about the springs, suspension, axles, the braking system and the wheels and tires. It is the unsprung weight of the vehicle that directly affects driving feel of a vehicle. The smaller the amount of unsprung weight, the more effectively the suspension will be able to do its “stabilizing” job on uneven roads. So reducing the unsprung weight will result in an overall better handling vehicle with a better driving feel.

-

Rotational Weight / Mass

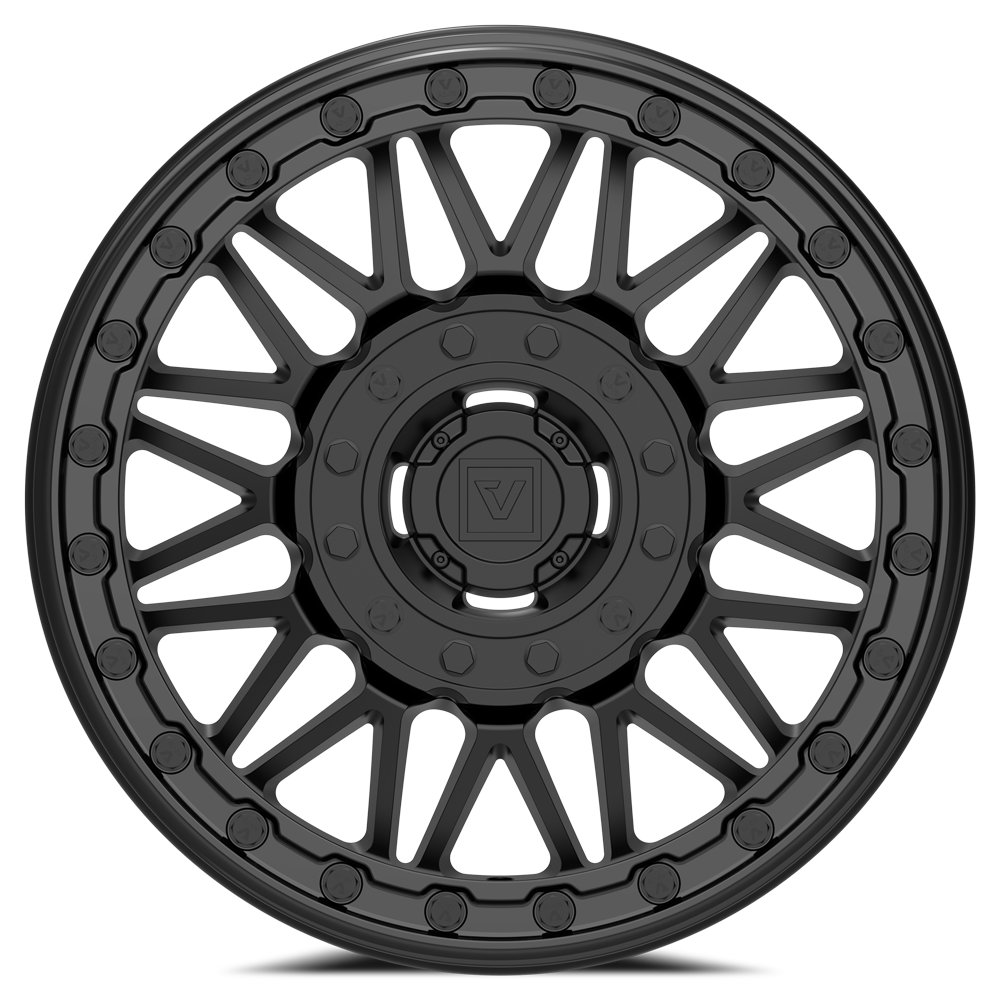

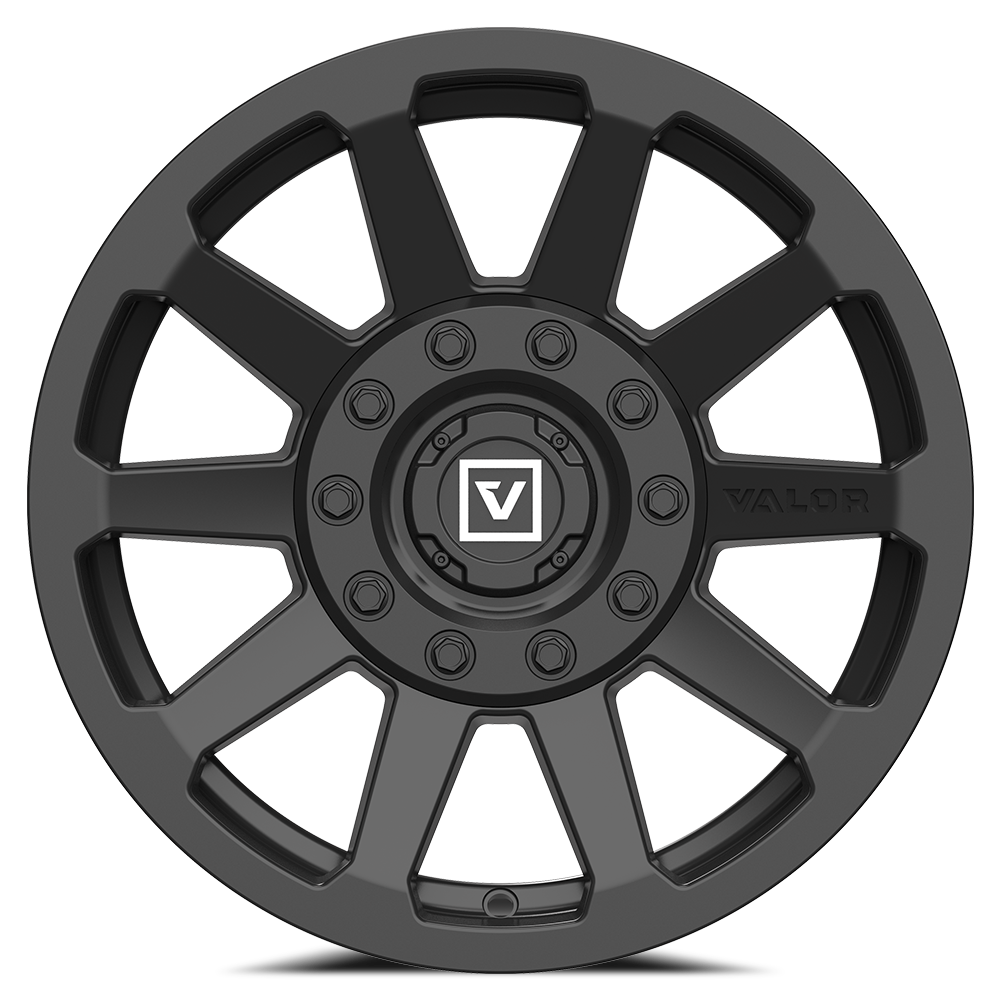

Additionally, we have the rotational weight of the vehicle. These are the parts that rotate, such as the drive shafts, wheels and tires. The amount of rotational weight will play a big role in the performance of the vehicle. The lower the weight of these components, the less energy is required to accelerate and decelerate. This will enhance the vehicle's performance. Additionally, the further away from the rotational axis the weight is located, the more of a negative impact it will have on performance.

For example, a wheel that carries more of its weight around the outer edge of the wheel will perform worse than a wheel of the same weight that has most of that weight closer to the hub.

Cutting weight from your wheels isn’t just about the weight you remove, but the physics behind how that particular weight’s location makes your vehicle behave. If performance is your goal, upgrading to lighter weight wheels can be worth every penny.

Rotational Inertia

Rotational inertia is the amount of resistance it takes something to change velocity. When it comes to wheels, it means a wheel with a higher rotational inertia needs more power to actually start moving than one with a lower rotational inertia. Rotational inertia is directly related to wheel weight, but it’s not as simple as heavier wheel equals slower vehicle.

Rotational inertia can be dramatically affected based on how wheel weight is distributed in the construction of the wheel. Weight that is centered closer to the hub results in a much lower rotational inertia than the same amount of weight found in the rim or lip.

For a simple way to think about rotational inertia, think about spinning a small weight on a string. If the string is only a couple of inches long, it’s not particularly difficult to get the weight moving. If, on the other hand, the weight is at the end of four feet of string, it gets substantially more difficult to get it spinning.

The effect of wheel weight on performance

As a performance rule of thumb, you always want to reduce as much weight from the un-sprung parts of your vehicle. This rule applies to any vehicle, and is typically one of the first areas end-users set their eyes on for immediate results. The wheels are the easiest and most cost-effective way to reduce un-sprung weight (the alternative is replacing expensive components like axles, wheel hubs, control arms, and certain driveshaft components).

There’s a ton of physics behind the full impact of un-sprung weight reduction, but generally speaking, any reduced weight makes it easier for the suspension to do its job more effectively. Reducing the wheel weight in a performance vehicle – especially one meant to take corners, means you’ll quickly find better handling behind the wheel. Less mass in motion also means you'll see notable improvement in your acceleration and deceleration times.

What wheel weight means for braking

Rotational inertia has a similar impact on braking as it does on acceleration. That said, it’s typically not rotational inertia that’s going to impact your vehicle’s ability to stop. It’s friction – your brakes – that will have the greatest impact.

The effect of wheel weight on fuel economy

Because wheel weight is rotational mass, its effect on fuel economy isn’t exactly a straightforward answer. If you’re doing a lot of stop and go (rock-crawling), you could see an impact on your gas mileage when you reduce your wheel weight. You’re using all that extra energy to get your UTV back in motion every time you stop or slow down.

If you primarily smash the gas and go wide-open, you’ll be less likely to notice an significant impact. Once heavier wheels are in motion, the vehicle isn’t working nearly as hard to keep them at high speeds.

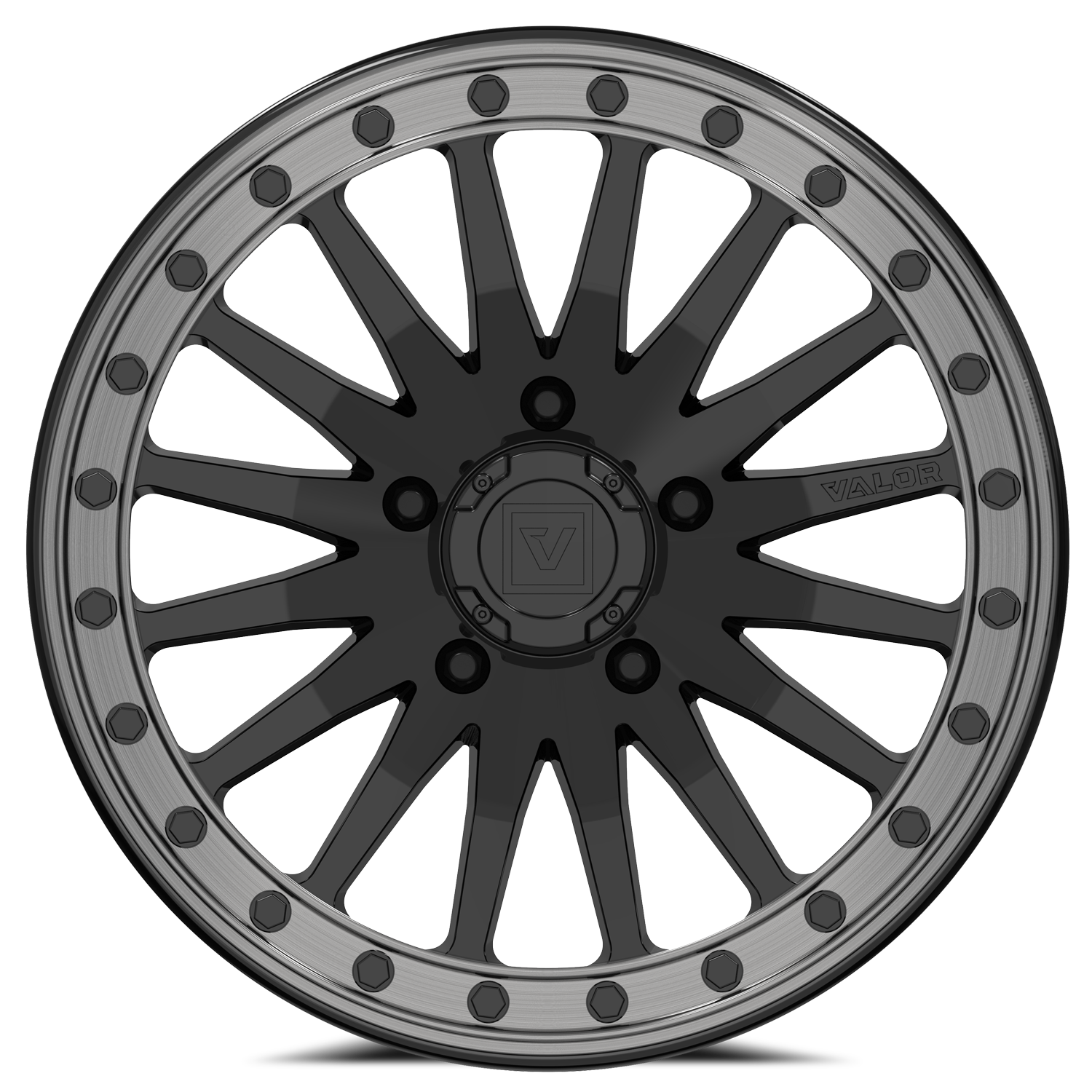

UTV Wheel Construction Methods

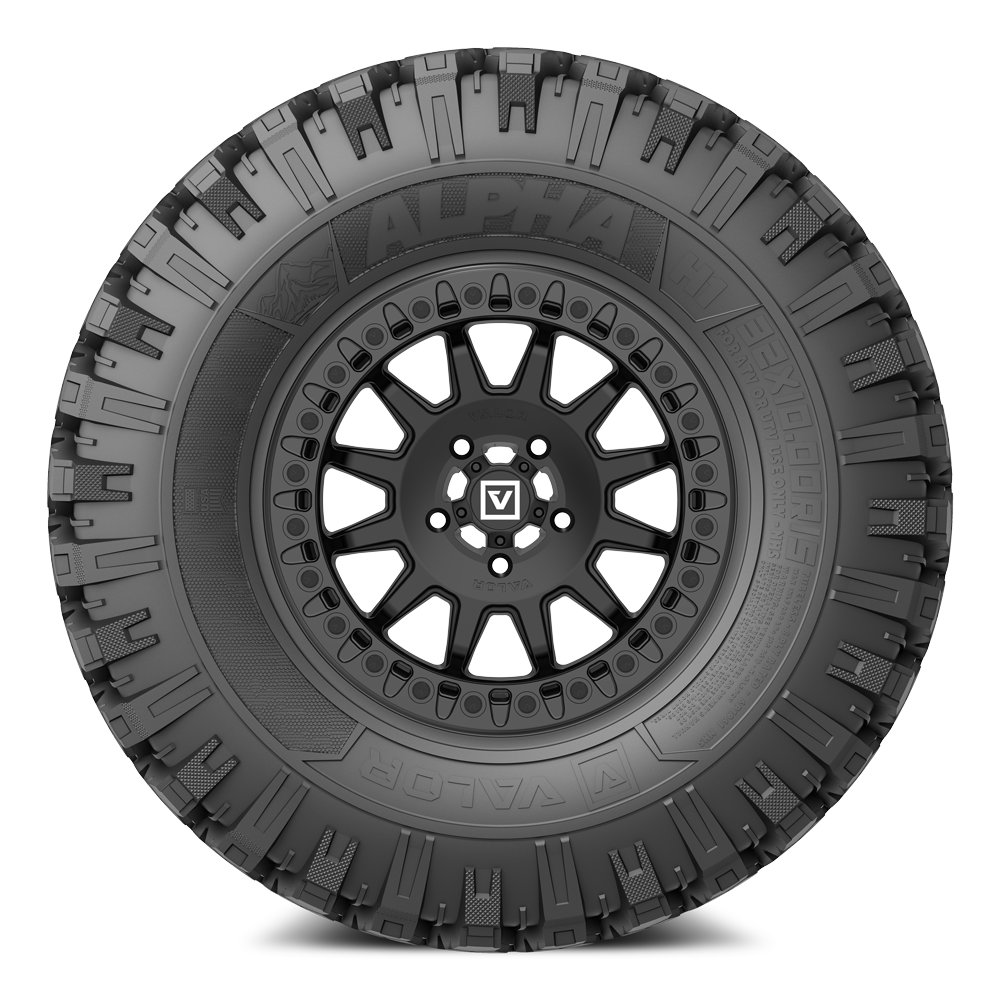

The popularity of alloy wheels has dramatically increased since the 1980’s. Alloy wheels are considered an upgrade from the standard steel wheel and consumers have watched as production practices have evolved over time. The three popular construction methods for creating a lightweight wheel are casting, flow forming and forging. Cast wheels offer the most style options. Flow form constructed wheels are both lighter and stronger than cast wheels, but cost more. The most expensive will be forged wheels, due to the intricacy and time requirements of the manufacturing process.

Casting – Aftermarket wheels are most commonly cast using a blend of aluminum and nickel. The material is heated to high temperatures, melted into a molten liquid, poured into a mold and cooled, creating a lightweight and durable wheel. The wheel is then drilled to specs and finished in paint or powdercoat.

Flow Form – Flow formed wheels are cast like any other wheel. However, once cast, the wheel is reheated to a high temperature and the barrel of the wheel is then pulled down and widened by spinning discs. This ultimately strengthens the aluminum while using less material to form the final shape of the wheel, compared to a fully cast wheel. This can shave off multiple pounds in larger wheels (18"+) however in smaller sizes (14"-17") the minor weight drop rarely justifies the additional price.

Forged – By far the most intricate and expensive process, forged wheels are constructed using a solid piece of aluminum called a mono-block. The mono-block is heated and pressurized to form the shape of the wheel. Once formed, the wheel is lathed and then precisely milled using a CNC machine to remove access material. This creates an incredibly lightweight wheel that is about 3 times the strength compared to a standard cast wheel. Unfortunately, the price goes up about 3 times compared to a standard cast wheel.

SO....DOES A LIGHTER WHEEL MAKE A DIFFERENCE?

Bottom-line, when installing heavier wheels, you are actually adding unsprung and rotational weight to your vehicle, which will have a more adverse impact on the handling and performance of your vehicle than any other similar weight added to the vehicle elsewhere.

In conclusion, it’s always better to install lightweight wheels when replacing factory wheels. If you really like a specific aftermarket wheel, at the very least try to match your stock wheel weight. When possible, going lighter than stock is always better. Running wheels that are heavier than your OEM stock will always negatively affect your vehicle's performance.