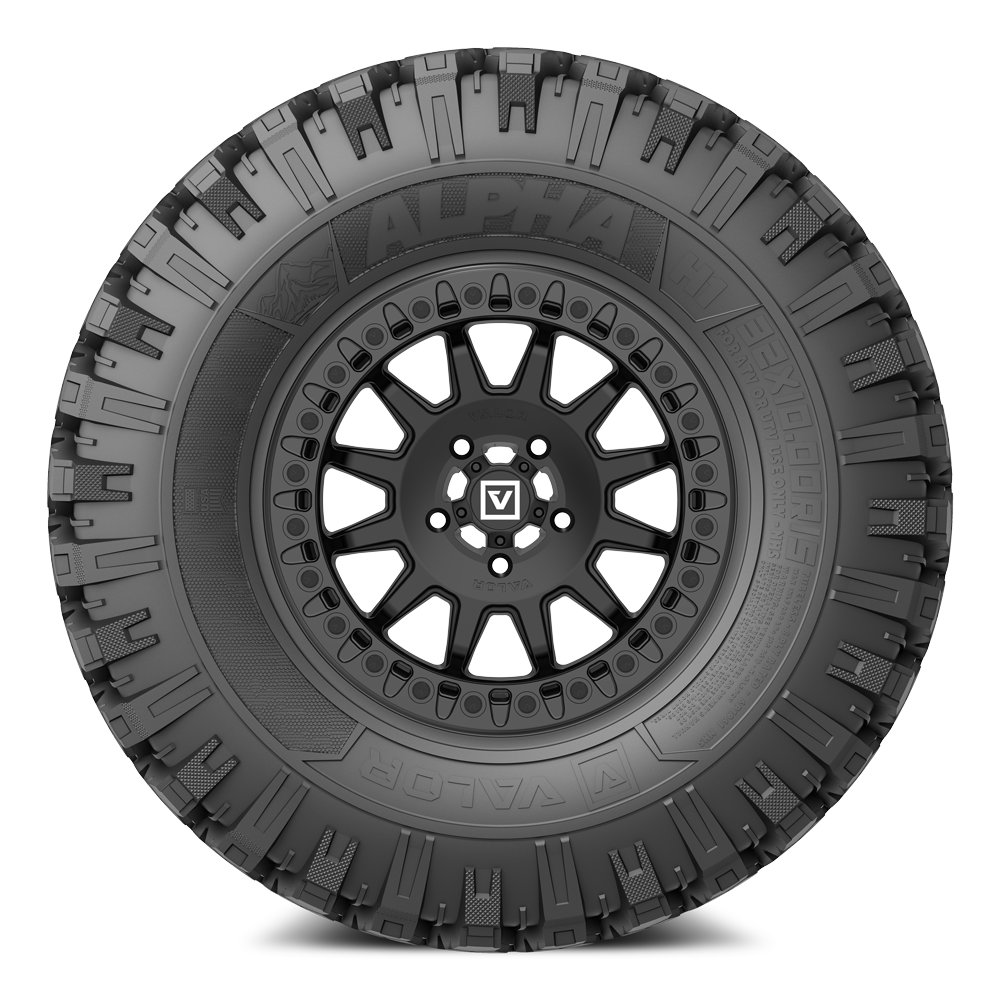

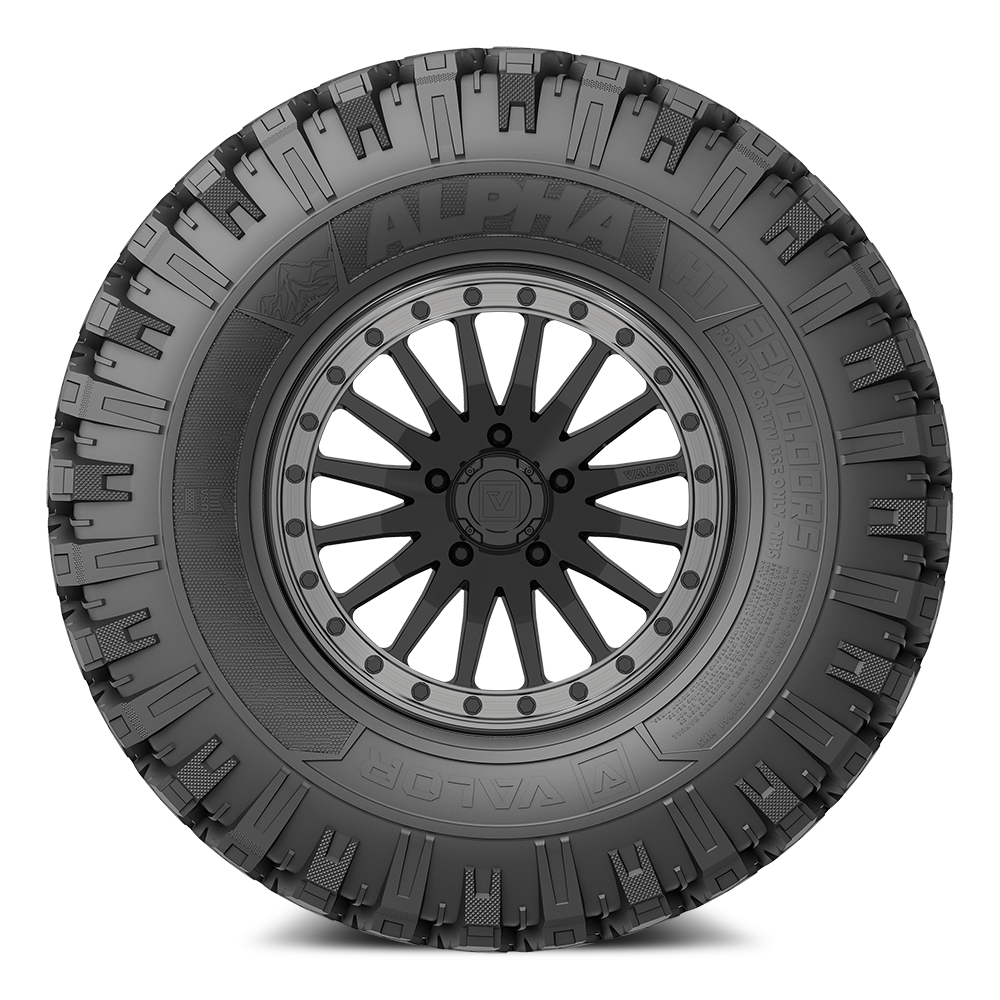

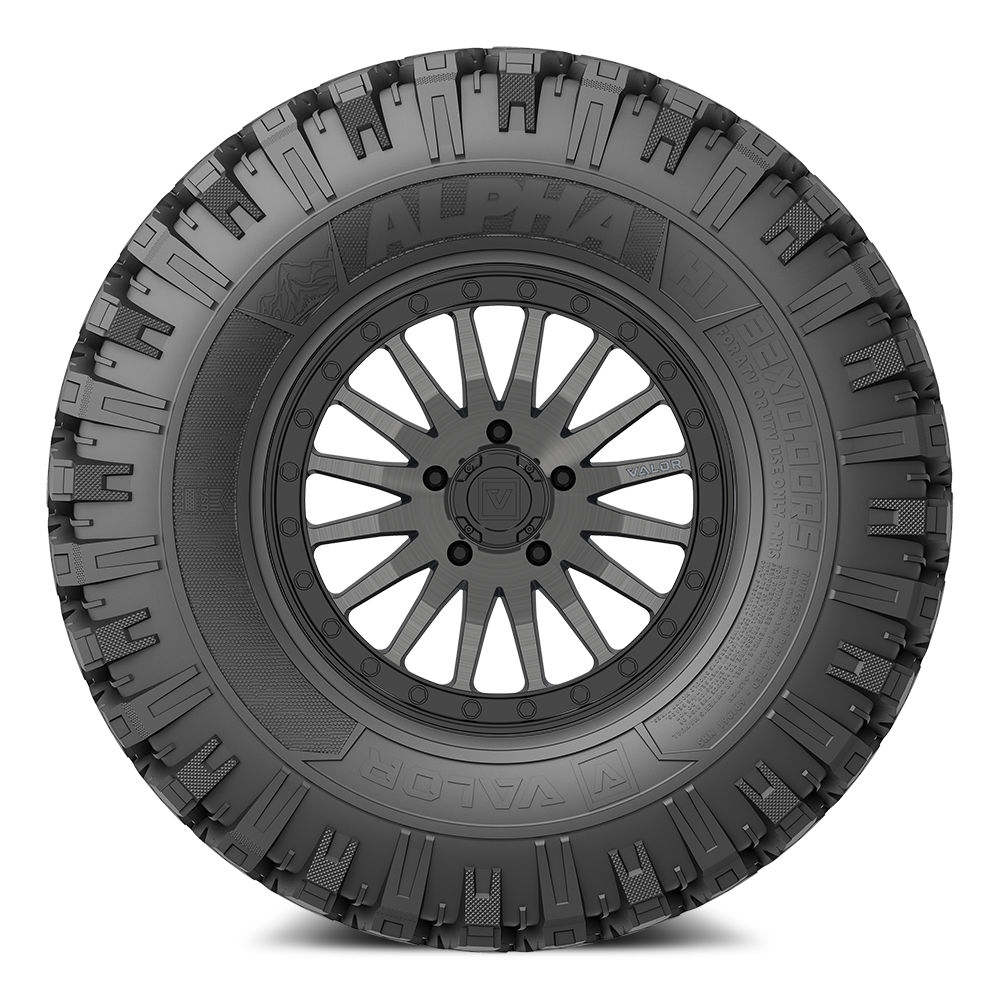

A tire is a complex combination of components made from several unique ingredients, starting with extracted rubber from none other than the rubber tree. But how do we get from the rubber tree to the trail? Tire manufacturing is a multi-step process requiring innovative manufacturing techniques and specialized machinery exclusive to the tire industry. Let's look at all five essential stages of tire manufacturing:

- Sourcing of materials

- Manufacturing of components

- Building the tire

- Vulcanization

- Quality control

Stage 1: Quality ingredients to make essential compounds

Raw materials are used to create the necessary compounds to finish a tire. Here is a list of the primary ingredients required for tire manufacturing:- Steel. This serves as the starting material for the manufacture of tire bead cores (steel wire). The bead holds air pressure and provides the tensile strength to ensure your wheel and tire stay intact under high speeds and through rough terrain.

- Chemicals. Synthetic rubber and materials are used to reduce tire tread wear, increase grip (wet, rocks, road, etc,) and extend the life of a tire.

- Natural rubber. Rubber is extracted from special trees (simply called rubber trees) grown in large plantations. The milky fluid (latex) that flows out coagulates when acid is added to it. It is then cleaned with water and pressed into solid bales for easier transportation and storage. Bales of natural and synthetic rubber are sectioned, cut into portions, weighed, and mixed with other ingredients according to precise recipes.

- Textiles. Base materials like nylon, polyester, and aramid fibers are commonly used for the manufacture of cords that serve as reinforcement in tires.

Stage 2: Manufacturing of components

- Steel cord. Pre-treated steel cord supplied on wire spools is fed into a calendar, where it is embedded in one or more layers of rubber. The result is a continuous sheet of cord and rubber. This is cut at a defined angle to the correct length according to tire size and rolled up for further processing.

- Tread. Kneadable rubber material that has been blended in a mixer is now ready to be made into the tread. A screw-type extruder shapes the rubber into an endless strip of tread. After extrusion, the weight per meter is checked and the tread cooled by immersion. The tread strip is cut to length for the tire size. Another unit weight control is then carried out.

- Textile cord. Textile threads are fed into the calendar by a large roller device and embedded in a thin layer of rubber. This endless sheet is then cut to the desired width at a 90° angle to the direction of travel and rewound for further processing.

Image below: nylon cord being embedded with layers of rubber on both sides

- Steel bead. The core of the bead is made up of many ring-shaped steel wires and coated with protective rubber. See image below of completed beads.

- Sidewall. Sidewall sections cut to suit the particular tire size are turned out with the extruder.

- Inner liner. A calendar forms the airtight inner liner into a wide, thin layer. A tire is a complex combination of components made from numerous ingredients.

Stage 3: Building the tire

The various semi-finished products come together on the tire building machine and are assembled into what is known as a “green tire.” This is done in two stages: the casing, and the tread/belt assembly. This “green tire” is then sprayed with a special fluid to prepare it for vulcanization. The various semi-finished products come together on the tire building machine and are assembled into what is known as a “green tire.”

Stage 4: Vulcanization

During the vulcanization process, the tire receives its final shape after being vulcanized for a certain length of time at a certain pressure and temperature. During this process, raw rubber becomes flexible, elastic rubber. Curing press molds are engraved with the tread pattern and sidewall markings. During this process, raw rubber becomes flexible, elastic rubber.

Stage 5: Quality control

Each individual stage of production – from the inspection of raw materials to delivery of finished tires – is subject to ongoing quality control. A multi-layered process ensures Continental tires are thoroughly checked for quality. Finished Continental tires go through: Visual inspection X-raying Various tire uniformity checks Once tires have passed all checks and inspections, they are sent to the distribution warehouse for shipment.